Videojet 8520 machine: How the machine was assembled and system configuration set up for the first t

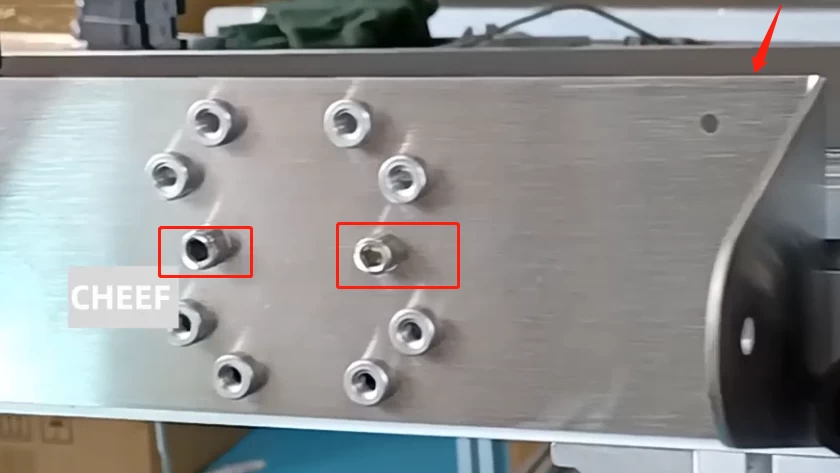

Install the sprinkler. The machine has a total of four nozzles, no matter how many nozzles there are, the installation method is the same.

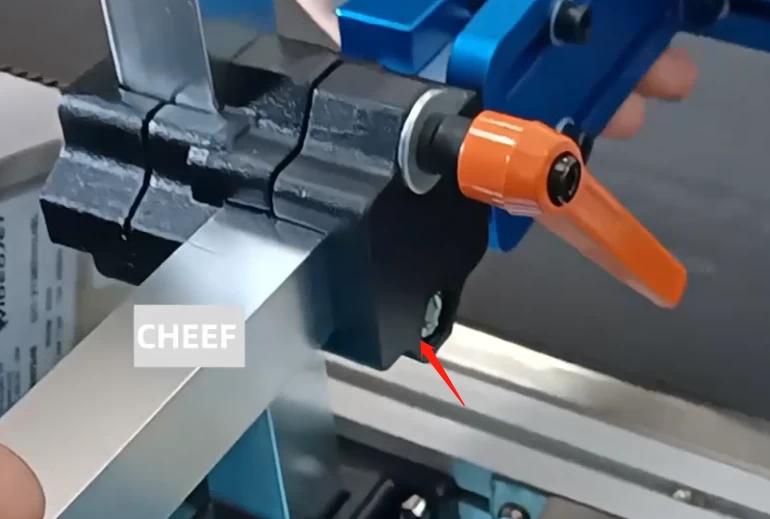

Fix the nozzle .

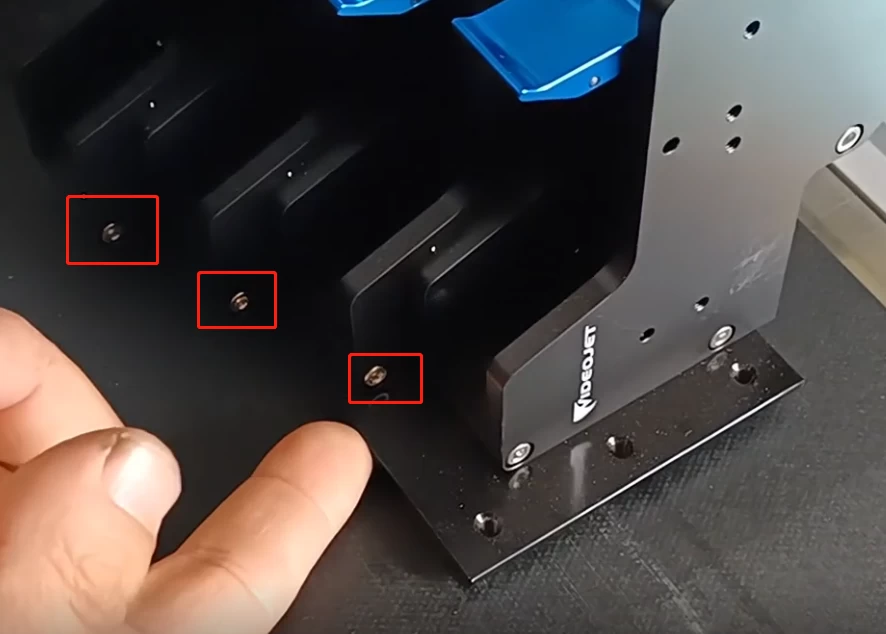

There are screw holes on the side of the first, second, third and fourth nozzles. Fix the screws in the holes and tighten them.

Then fix the screws of the combination board below. The combination board is used to fix the lower part of the nozzle. Tighten these three screws.

We first assemble the sprinkler head, after assembling, install the lower combination board, and the sprinkler head is fixed.

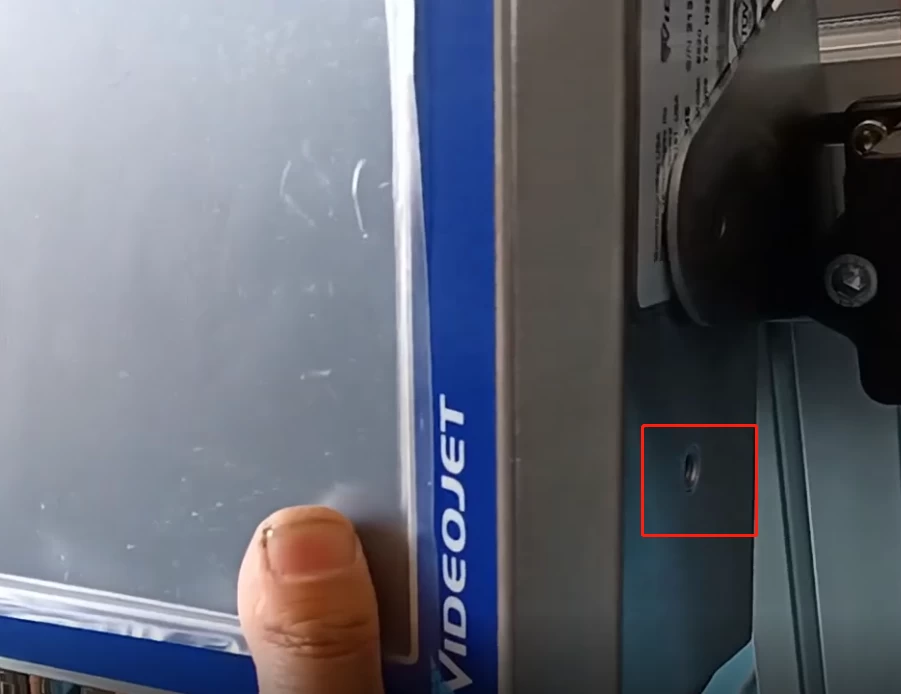

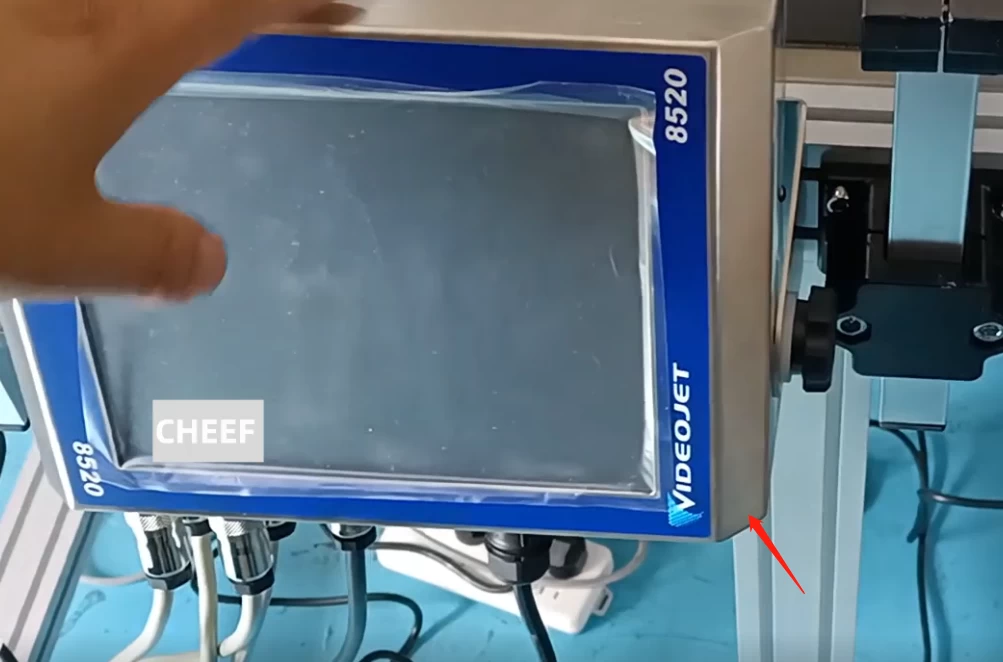

Install the controller. First install the fixing plate on the side of the conveyor belt, there are two screws on it, and install it through the holes on the aluminum profile.

There are holes on both sides of the controller, we tighten the fixing screws on both sides, so the controller is installed.

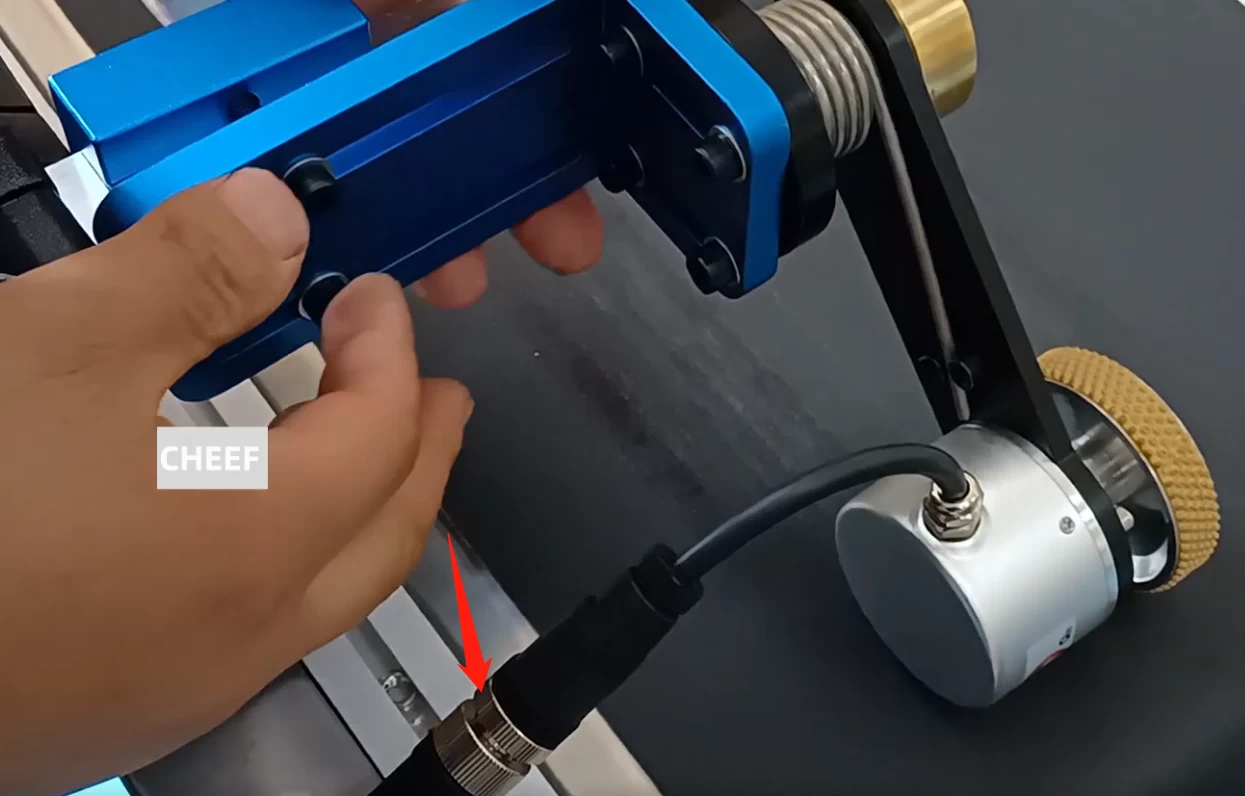

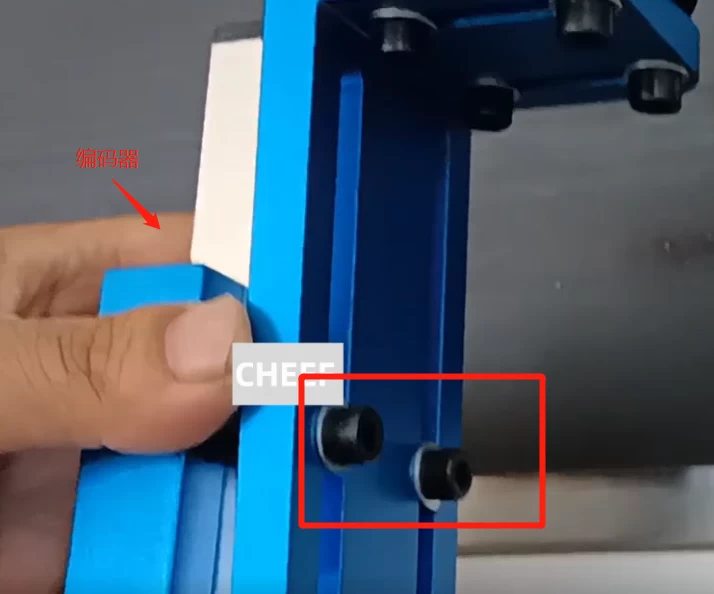

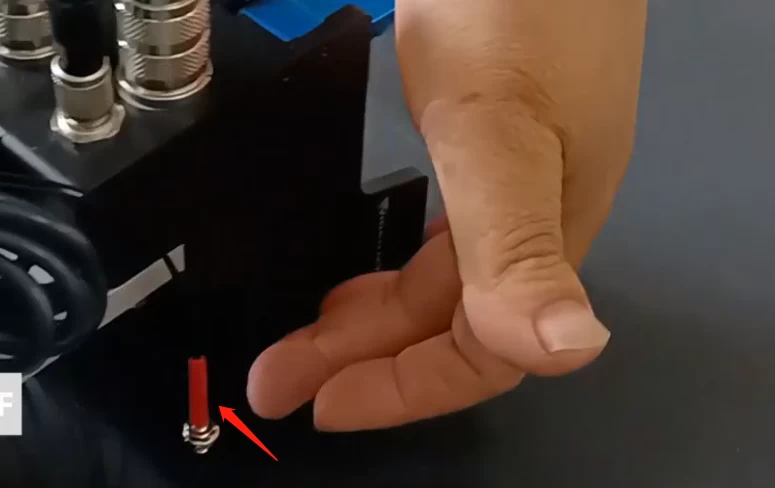

Install the encoder wire first.

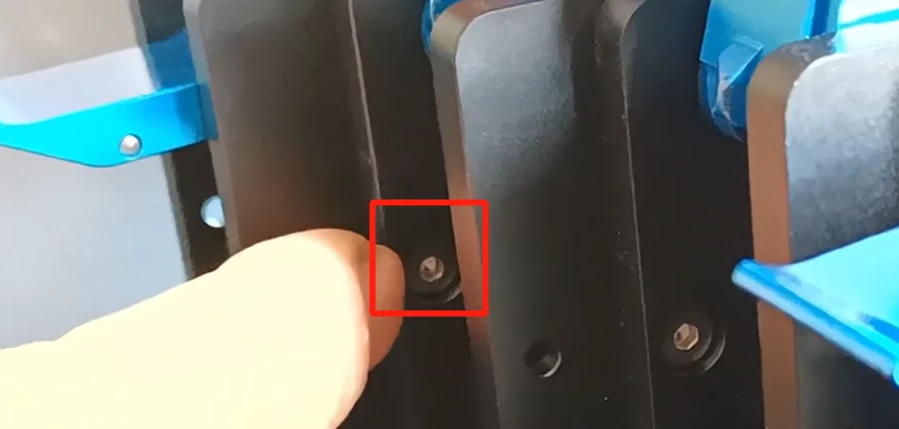

Loosen these two screws first, you can take out the encoder.

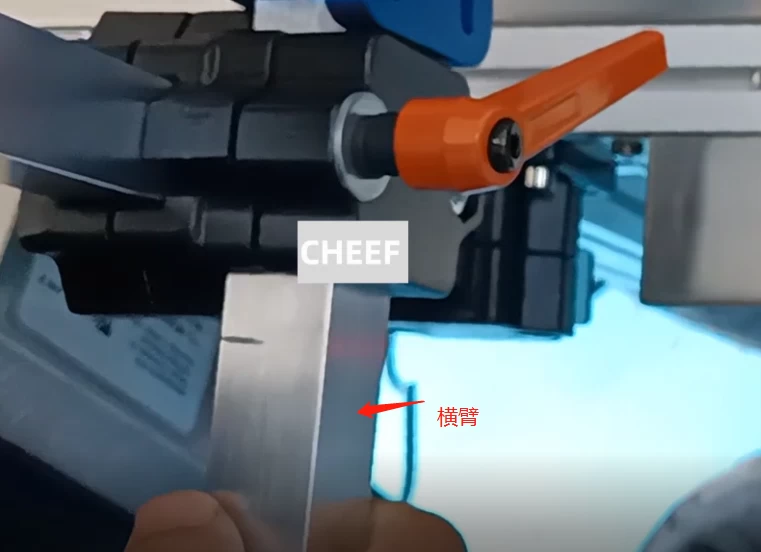

This is the cross arm, the basic structure is like this.

Installing this machine requires a certain amount of resistance, you can install it on this side or on the opposite side.

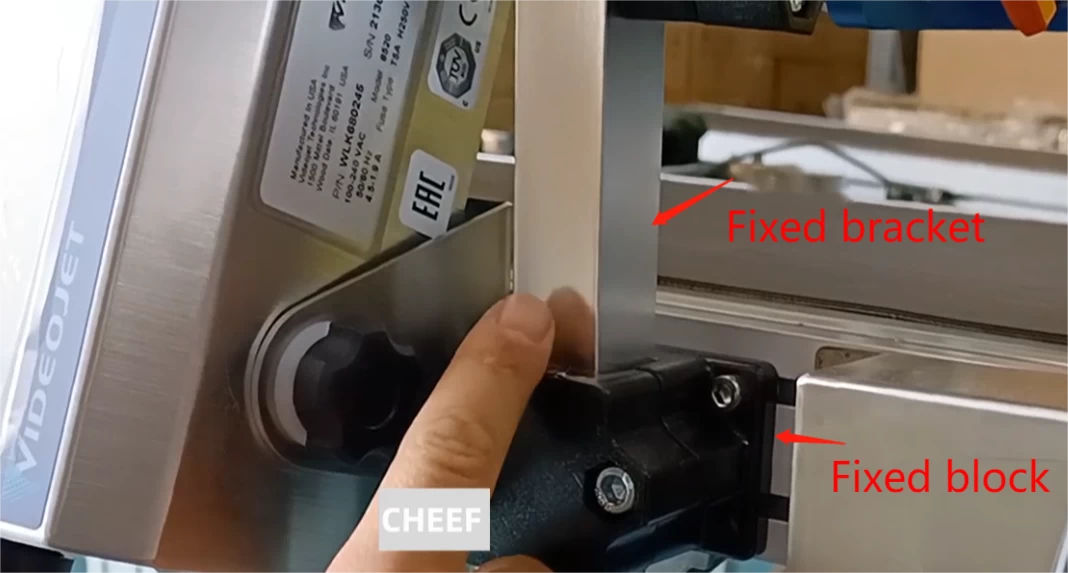

The lower fixing block is also fixed on the aluminum profile, with a fixing bracket .

Here it is fixed in this position with an adapter.

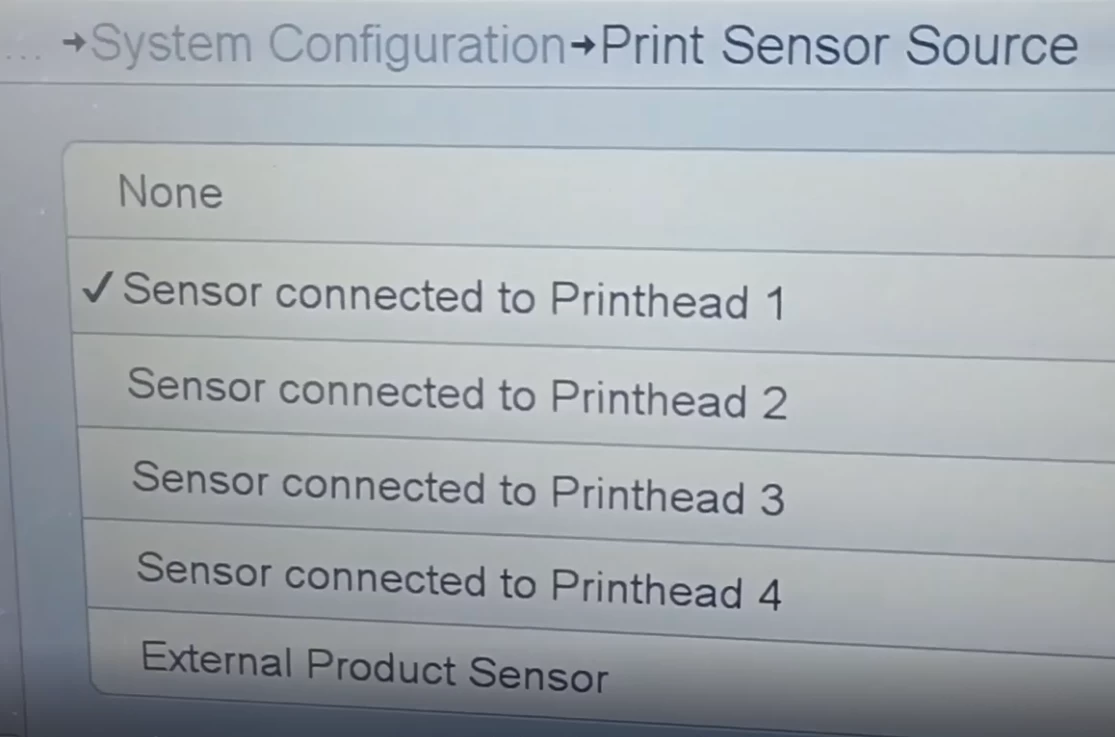

This is a photoelectric. Be sure to remember whether this photoelectric is placed on 1 or 4. If it is placed on 1, you must select the photoelectric above 1 when setting it.

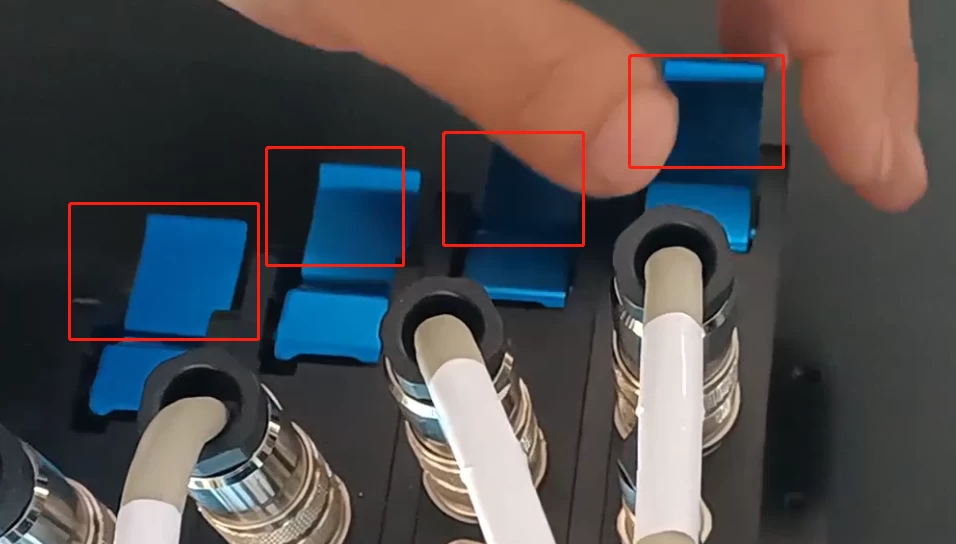

The four lines above are arranged in sequence as shown in the figure, and the line with the corresponding serial number under the machine is connected to the corresponding nozzle.

These four white lines are the four lines of the nozzle, which are marked with serial numbers; the lines of the encoder are marked with ENC.

Note: The distance between the nozzle and the surface of the product should be about 2 mm, preferably within 2 mm, the closer the better.

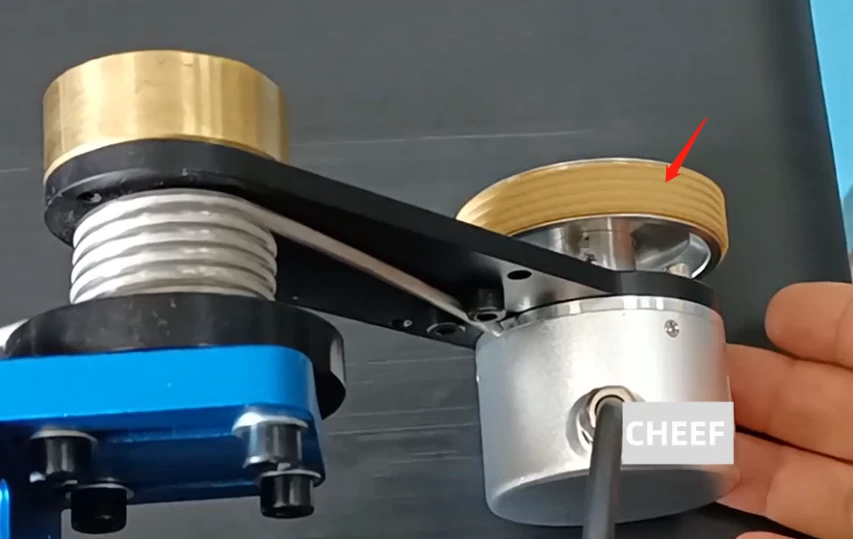

Look at the direction of the conveyor belt, we stand behind the nozzle, we can see that the conveyor belt is turning from left to right.

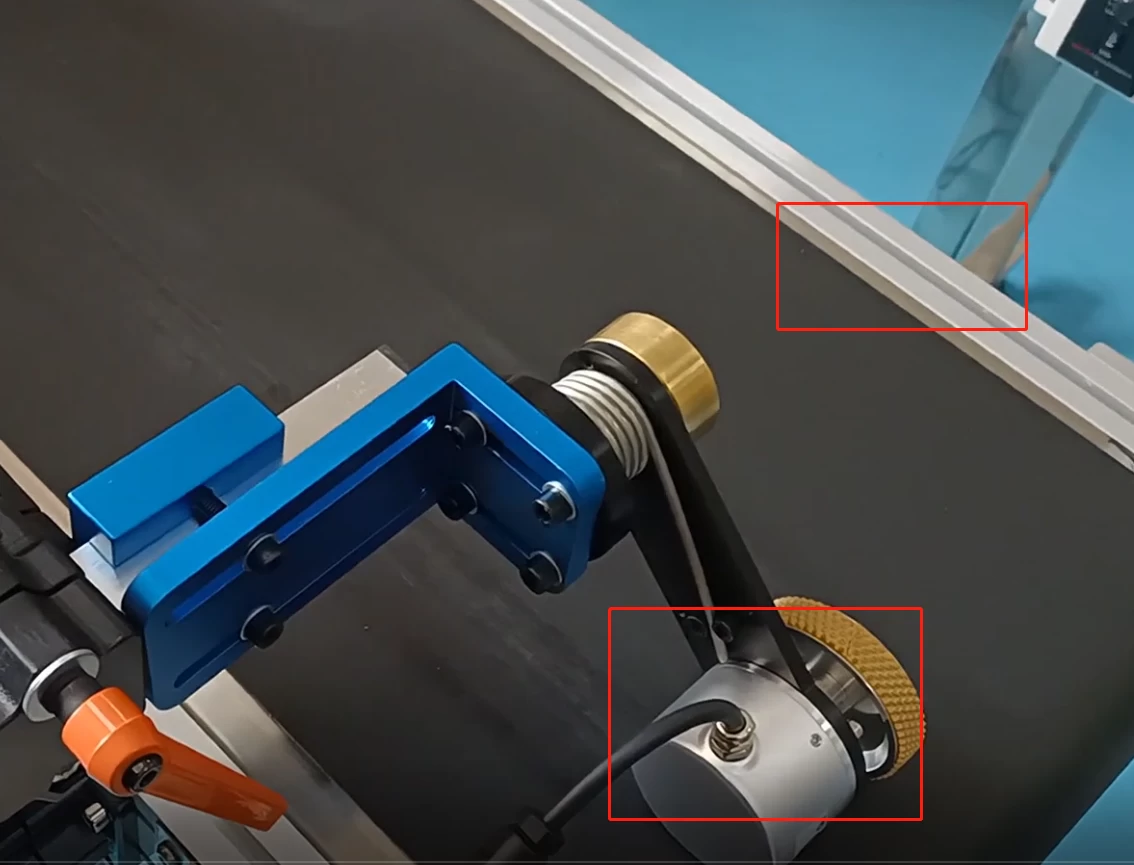

The encoder is also rotating, because there is a certain resistance, so the encoder is also rotating, so the basic installation of the machine is no problem.

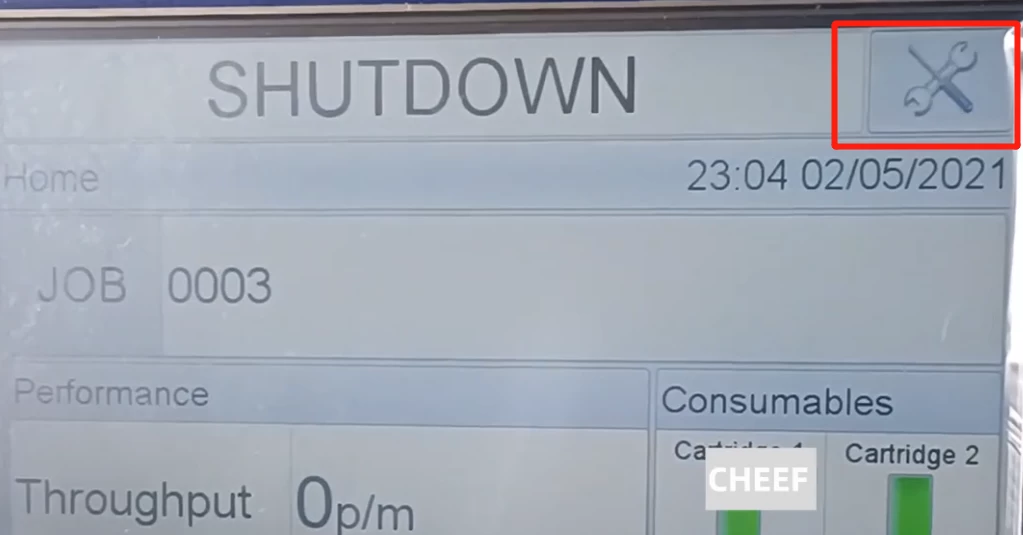

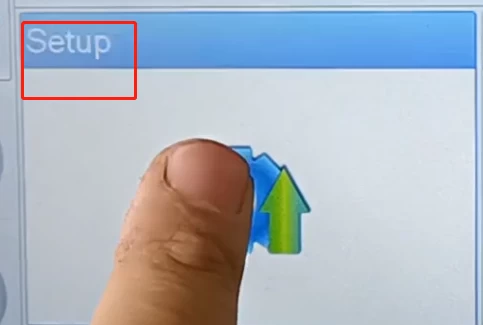

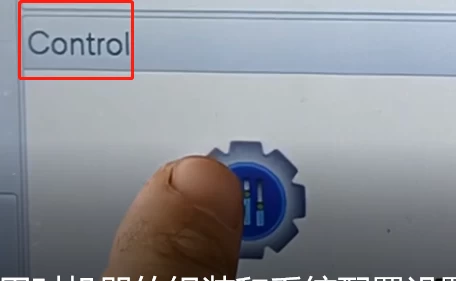

The machine is assembled and set up first, and then the machine is set up. When the machine is first received, we need to set it up.

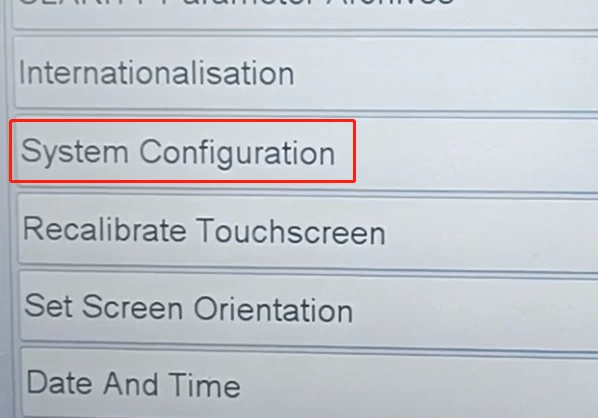

After selecting the system configuration, click Next, you can set the language, date, time, etc. as needed .

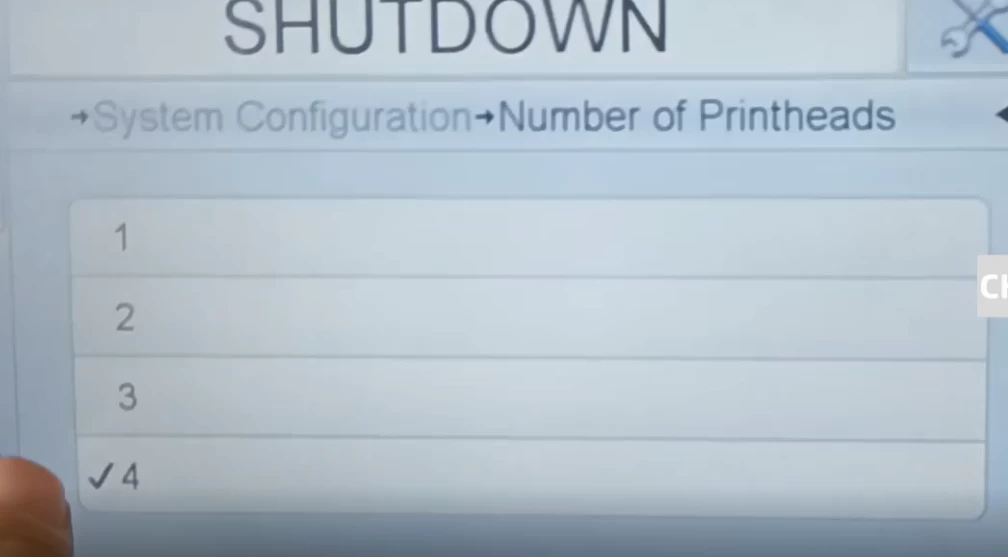

After the date language time is set, click next, this machine is 4 print heads and together, so choose 4. Next select 4 as well.

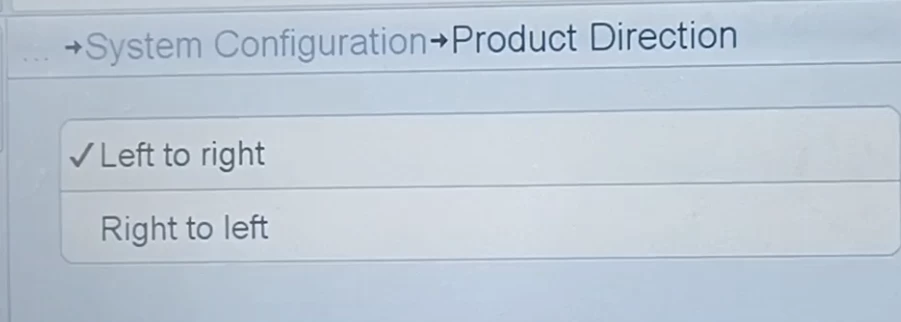

When selecting the conveying direction, we stand behind the nozzle, and we can see that the conveyor belt is turning from left to right, select the first option.

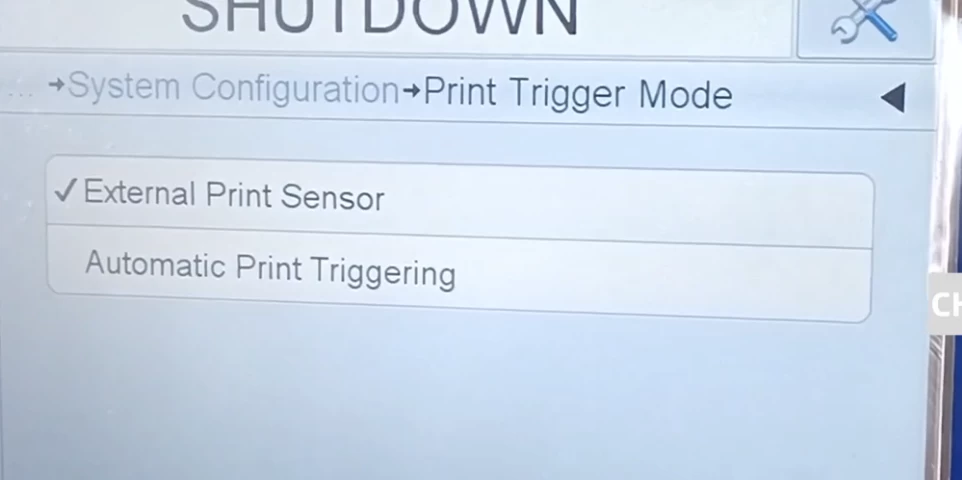

Whether the sensor is internal or external or automatic, this machine is external.

Which nozzle is the sensor installed on, this machine is installed on 1.

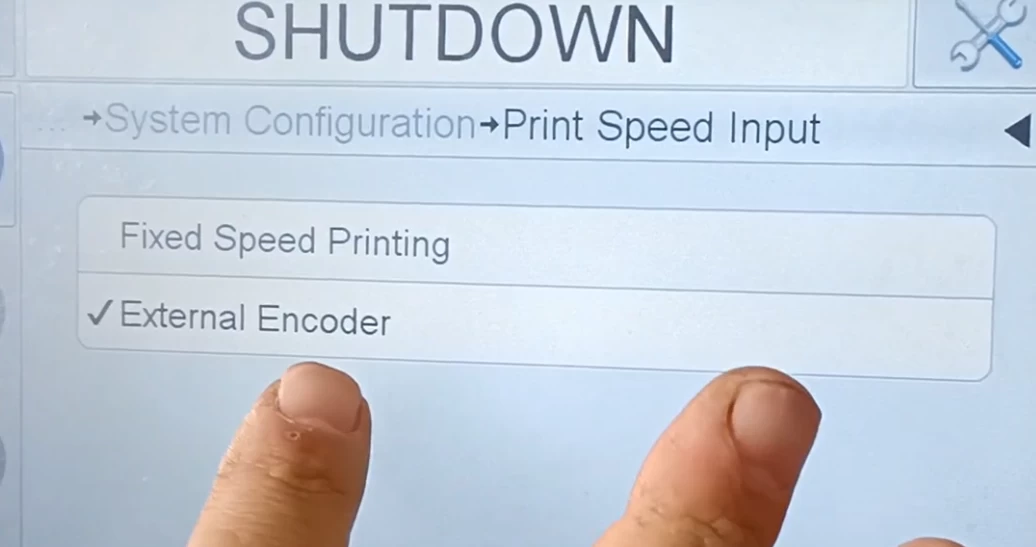

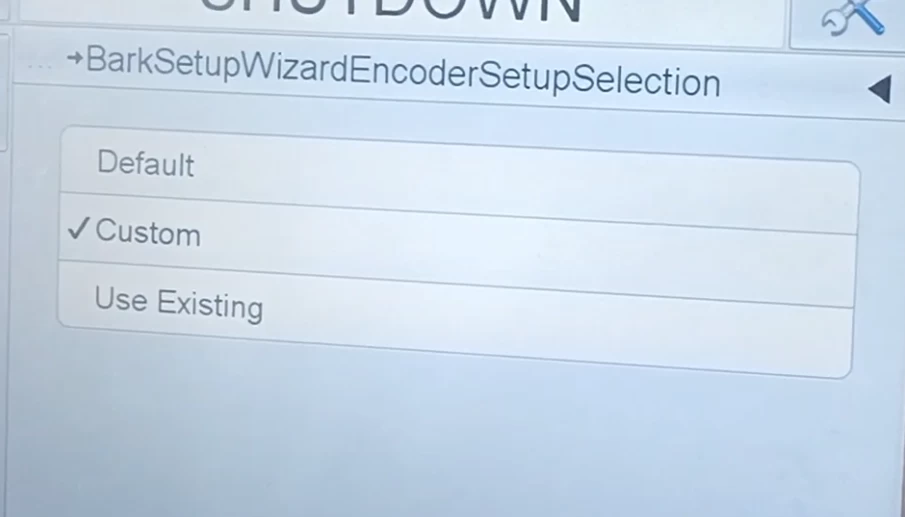

Select the printing method, we choose the encoder mode, because the encoder mode used, select the encoder mode, the encoder mode has default and custom, we choose custom.

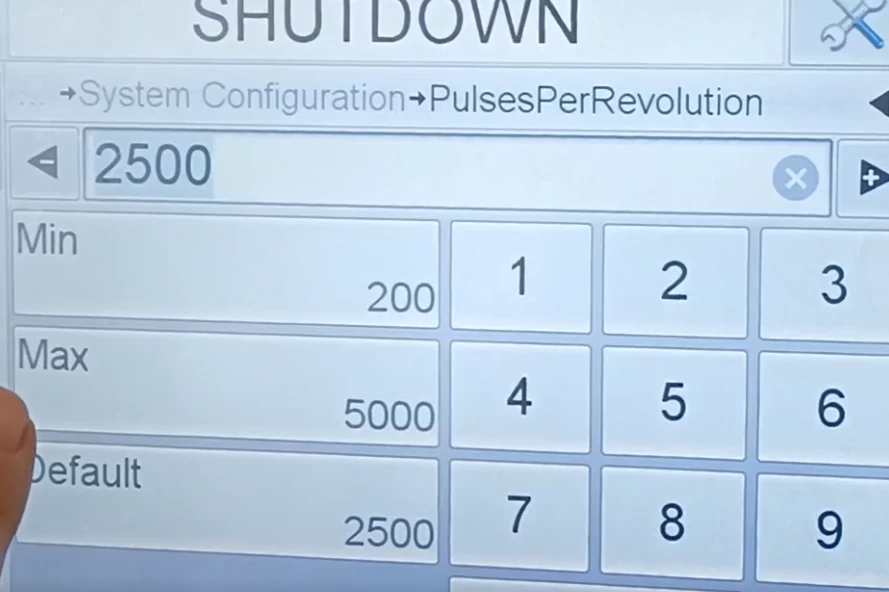

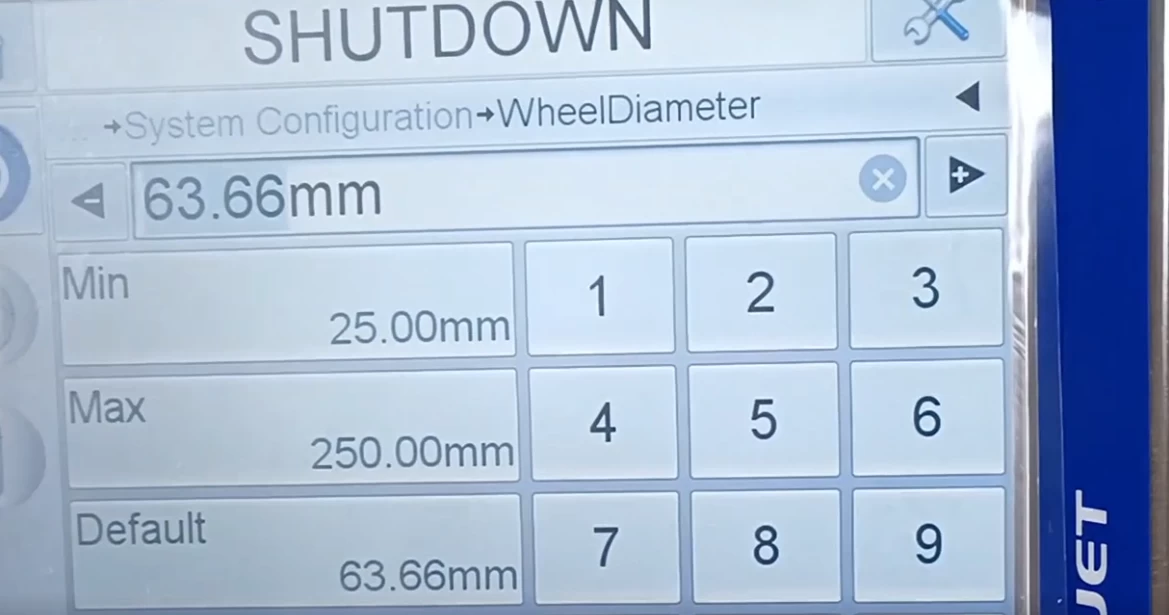

Here you need to set the pulse, the specific value depends on the number on the encoder; the diameter also depends on the encoder, the original encoder is used, and the diameter is 63.66.

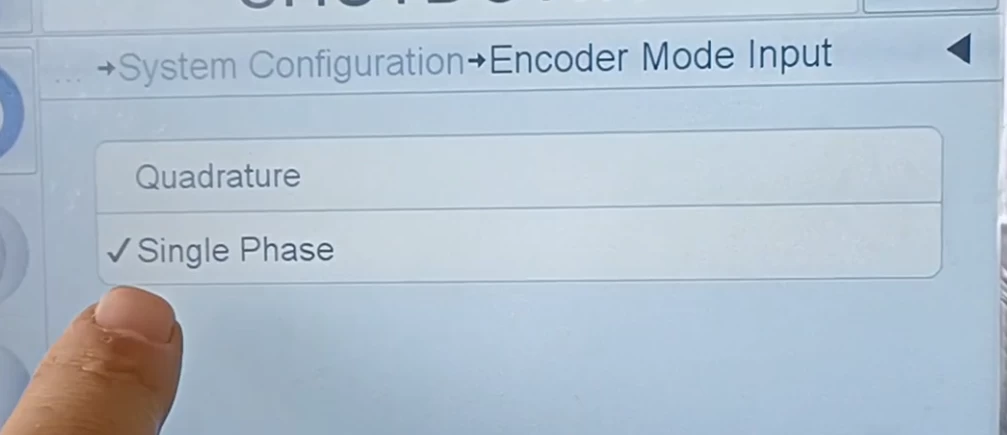

Then set the encoder mode input, and the system setting is completed. Only use the mentioned parts, and the unmentioned parts can be ignored.