How to deal with the high voltage fault and recovery fault of Domino A200 inkjet printer?

If it reports a high-voltage fault, let's first look at whether there is ink on the high-pressure deflection board, if there is ink, we use cleaning liquid to wash it clean, then blow-dry it, and then turn it on to try:

If there is a recycling failure, we must first consider whether the nozzle is blocked, if the nozzle is blocked, we have to clean the nozzle, because it is not the same as the A plus machine, the A plus machine has the function of cleaning nozzle, this A-series machine does not have this function.

Under normal circumstances, we can do this: if the machine is turned on or off normally, it is also feasible for us to clean the nozzle in this way:

Because if you're normally turning on and off normally, it automatically cleans the nozzle, and then we can wash the nozzle with cleaning fluid.

If the ink line is not entering the recycling tank due to a deviation of the ink line and then reported a recycling failure, then we have to adjust the screws.

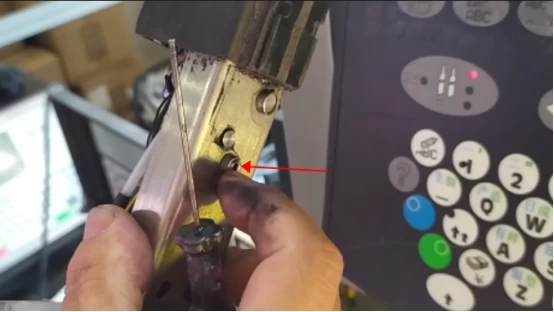

This is a fixed screw, whether you want to adjust the ink wire to the left/right or forward/backward, first loose this screw:

Loosen the fixing screw, and then adjust the screw, which adjusts the left and right of the ink wire:

This screw adjusts the front and back of the ink wire:

We have to look at the actual situation, to see whether the ink line is up or down or left or right, and then adjust.