TIJ inkjet printer for traceable system customizable coding software

With the economic development and the upgrading of the consumption structure, people are paying more and more attention to the quality of goods, and the demand for high-quality goods is growing. Therefore, a traceability management system was established to achieve anti-counterfeiting (recognition of true and false) and traceability (tracking back to the source) of products through statistical product data. Scan the barcode of the package, establish the relationship between the package and the product, complete the warehouse scan and trace the after-sales service, and link all the raw materials, components, suppliers, customers, production process and quality through any bar code information of the package or the product itself. Key information such as inspection. The traceability system has been widely used in various industries. In the food industry, the traceability system mainly covers the upstream and downstream of the entire food industry chain such as food production bases, food processing enterprises, food terminal sales, etc., and is used exclusively by similar bank cash machine systems. Hardware devices share information and serve the end consumer. Its value can be seen from the following two aspects:

1, for the business

It can improve the management efficiency of enterprise merchants, improve brand image and popularity, effectively protect brands and prevent dumping and counterfeiting.

2, for consumers

Increased the safety and credibility of consumers, the products can be easily found to the source, to a certain extent, to enhance the trust of consumers, so that consumers can use the comfort and ease of eating.

The anti-counterfeiting traceability system keeps the anti-counterfeit label information encrypted and categorizes the product information, refines the production process to each key control point, clarifies the responsibilities of each key link, and completes the safety quality management of “recording with production and leaving traces of the process”. mode. Each product has a specific two-dimensional code. After scanning the QR code, the consumer can obtain the date of production, the place of production, and the information of the product, thus completing the traceability of the product.

Then, what kind of code type is required for the "code" of the product and the code required for product traceability?

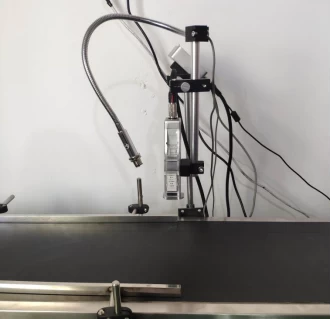

The CHEEF TIJ inkjet printer is one of the important forms. The csv file can be imported through the U disk, or the host computer can send data to the inkjet printer in real time. The code matching control system and the system data center (including the data interface server, the data processing server, and the database server) can spray the database information. Achieve one-to-one code, product anti-counterfeiting trace printing. This inkjet printer is a thermal foaming printer. It uses a small heating resistor to heat the nozzle nozzle to make bubbles of ink and spray it onto the surface of the product to realize the technology of marking printing, also known as high temperature and high pressure printing technology. The advantages are: high precision printing; convenient maintenance; good printing effect; low equipment cost; high speed coding, high efficiency; The device uses only ink cartridges, and without the consumption of solvent, it will not cause damage to the environment by methyl ethyl ketone, acetone or alcohol. Pharmaceutical manufacturers of GMP standards can also use the coding equipment to identify the traceability information of the product in real time.

The CHEEF TIJ printer has a fast printing speed and can reach a line speed of 120 m/min at 150 DPI resolution. In the normal 300DPI resolution state, the fastest speed is 60 meters / minute. Its own software can realize a printer control line in the central control room. Very suitable for large industrial enterprises. For example, it is matched with the online instant printing of the product box number and the logistics trace code in the sealing machine or assembly line.

Compared with the traditional inkjet printer, only one color can be printed, either black or white. The snow Philippine TIJ printer can select a variety of color ink cartridges, such as black, white, yellow, blue, red, etc. Meet the ROSH standard. The equipment has CE and FCC certification. It can also print graphics, text, QR code, database information, pictures, etc. The barcode QR code has more than 10 formats such as QR, the resolution is 50, the maximum is 600DPI, and the code is formed once. The printing font can be as small as 1mm, with high printing resolution and high stability. The font can be up to 76mm. Therefore, it also has an important application, which is an online printing of the product ingredient list of the carton outer packaging. As long as the pre-printed information such as the trace bar code is input into the TIJ printer, the code can be printed online at one time. Can increase production efficiency, reduce costs and reduce losses.

CHEEF TIJ printer has many outstanding functions: it has powerful external communication capability, RS232 and Ethernet communication protocol, which is convenient for industrial automation integration, and can easily transmit information with the host computer. It can also be equipped with an alarm light. When the ink is exhausted or there are other faults, the user will be alerted to troubleshoot. This machine has a multi-language system and is suitable for export to other countries. Including: Chinese, English, Japanese, French, German, Spanish, Portuguese, Russian.

At present, many manufacturers are replacing traditional machines with this inkjet printer. For example, Unilever, Mengniu, Jiajia Soy Sauce, Tide Washing Powder, Tianma and other enterprises are using this machine, involving the fast-moving industry, medicine. Industry, electronics industry, etc. We believe that our equipment can bring a better application experience to a wider range of customers.