How to handle Domino A120 inkjet printer viscosometer failure?

For general problems, for example, the viscometer has no value. It may be necessary to check whether the viscometer valve or the viscometer pipe, or the glass pipe in the viscometer is unblocked.

If the viscosity value of the viscometer does not come out, generally, you should see whether the viscosity exceeds the standard. If it exceeds 255, it will not display. If it is lower than 40, it will not display whether the viscosity is low or high. First, see if the ink viscosity is too thin or too thick. Why is it too thick? Is the solvent not added? Is there a problem with the solvent valve? These should be taken into account.

Because it is rarely caused by viscosity. Generally, it is put for a long time. It is relatively dry and sticks to the beads. At this time, poke the beads. Generally, this problem will be solved.

The pipe rarely sticks because it is so thick:

Unless you don't use it for months, and then it is dried out, and there is always ink residue in the glass tube, the beads will not be detected.

If the ink path is sealed and not dry, this problem is not easy to occur.

For A120 and A220 machines, viscosity fault is the most common fault. For example, the valve is stuck, or the ink of the glass tube sticks to the steel ball, or the pipe is blocked, or the ink supply or which way is blocked will cause this fault, which needs to be checked a little.

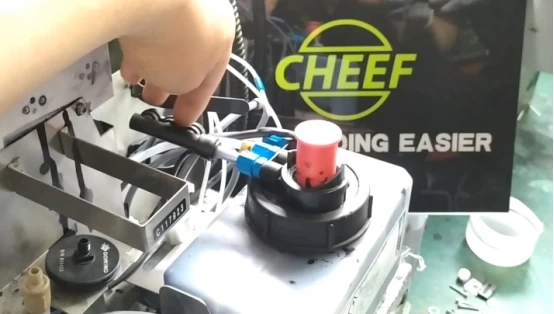

If there is no ink on the valve side, you open the valve, you supply ink, you completely remove it to see if there is ink:

If it has ink flowing down, either the valve, or the tube, or the viscosometer, bit by bit to check.

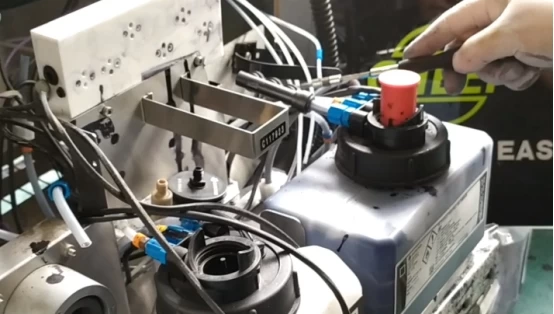

First exclude the viscosometer because the tube above is connected here:

So pull out the pipe below and blow it, it's accessible, it has to be very smooth, and then the steel beads inside will crackle, the general viscosity meter is no problem.

Then there is the line, the line is a problem with the board or valve problem, there is a viscosity meter line whether there is a problem, and finally check the motherboard, bit by bit to eliminate.

Machine conditions can occur, such as this has been blocked before:

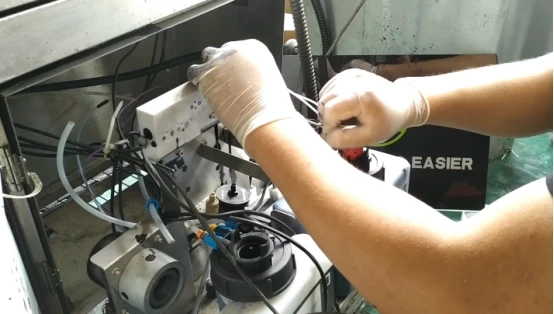

So all the lines should be kept open, as long as there is a pipeline, whether blocked or completely unobstructed or a little bit, will cause different problems.

After removing, we have to ensure that every pipe and every accessory should be smooth, otherwise we install them, if there are other problems, the inspection of the workload will be much greater. Then there is when you take down the machine, replace the filters as well.

This is now equivalent to a relatively large maintenance, if the gun body and nozzle on the sprinkler to replace, it is basically a new machine, it must be very stable, because there are no impurities and so on:

If you repair the machine like this, you won't have much problem in a year or two.

If it is ordinary ink, the general machine is not a problem, special ink time is longer machine may have some problems. Especially high-speed ink, the pipeline is best regular maintenance, otherwise it is more slag, especially it is easy to block the nozzle, and it is not like ordinary ink as a gentle punch off, it is not easy to fall off, stick to the high-pressure deflection board will also easily cause high-pressure failure.