IMAJE 9040 Repair Guide - How should clogging of recycling tubes and viscosometers be resolved?

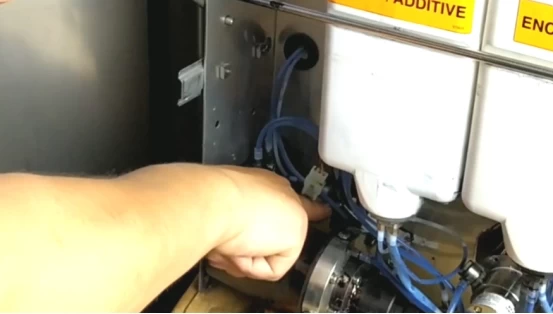

And then there is the pipe. If we find a place blocked, for example, the recycling pipe is not recycled, then we can pull out the recycling pipe directly:

Then we can short-circuit the recovery valve here:

Then you can blow it from this side. In this way, even if the vacuum pump doesn't work, it can return to the main ink tank:

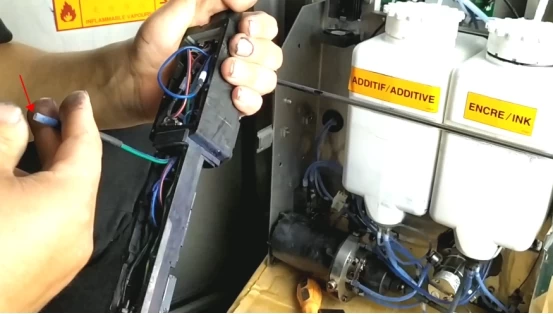

Blow hard. If the blockage is not very severe, use the ear ball to suck some cleaning solution to blow. Generally, it can be unobstructed.

If the blockage is very serious, we have to check which section is blocked, because the recycling pipe is also divided into several sections, so are all the pipes, whether it is the ink supply pipe or the recycling pipe. If it is blocked, we have to check it section by section, first determine the small direction, which side is easy to block.

Especially for the recovery part, it is necessary to determine whether the recovered iron crutch is blocked or the recovery pipeline is blocked:

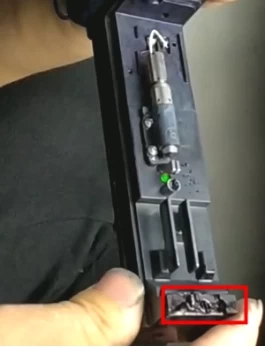

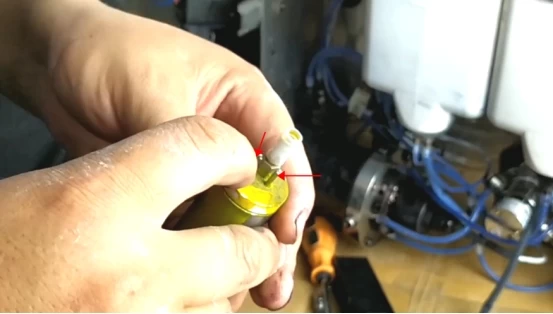

This is a viscometer. There is a thimble on it. One thimble controls the low one and the other controls the high one:

Then we turn it on, this is low, this is high:

The ink will flow in from this pipe, and then fill it up. When it reaches the low level, it will start to count:

If there is no fault in your viscosity system, the viscosity will come out immediately. Then when it reaches the high level, the viscosity valve will open immediately, and the ink will be pumped out from this hole:

Then it continues to pump away after a period of time. If it finds that the viscosity is high in the process of extraction, the solvent adding valve will open, and then add solvent into it:

The viscosity of the machine that was repaired this time didn't come out. Finally, it was found that it was full of dry ink lumps after opening:

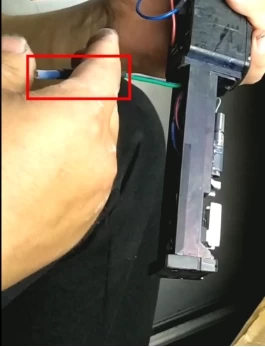

Normally, we first look at this viscometer to see if it is blocked,

At the beginning, our direction was also wrong, because at the beginning of blowing from this side, all pipes were unblocked:

But we didn't take it apart to have a look, and the viscosity didn't come out. Finally, after opening it, we found that there were a lot of dry ink in it:

Although the pipeline is connected, it will affect the flow of ink and its detection, because it will feel that there is always ink, and then the viscosity valve will be continuously drawn out, and it will sound all the time.