How to dredge the ink supply pipe cleaning pipe and recycling pipe of Imaje S8 / 9040 inkjet printe

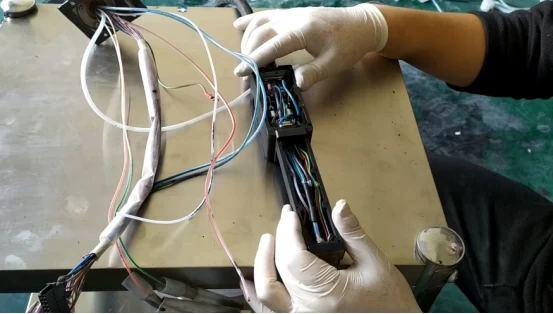

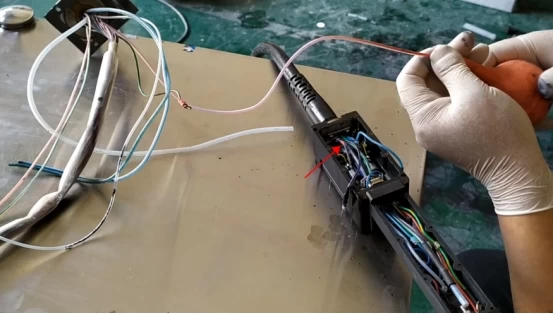

Let's see how the pipe of the pipe of the S8 and 9040 machine that is not used for a long time can be unblocked. Then we take apart the back cover of the printing head:

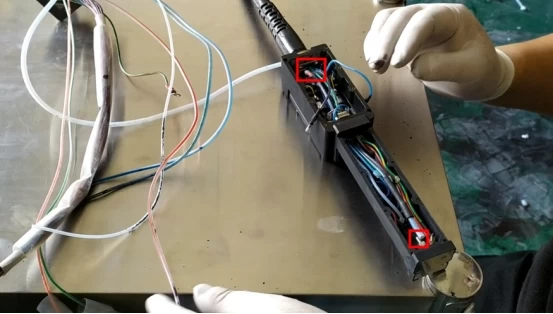

After removing it, we cut off the ink supply and cleaning tubes and pulled out the recycling tube:

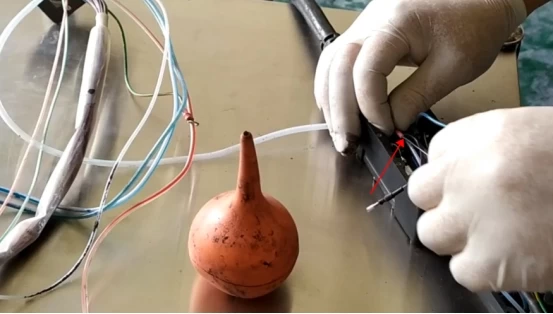

Then we can blow the ball at one end with the earwash ball and blow hard to see if it's going to work:

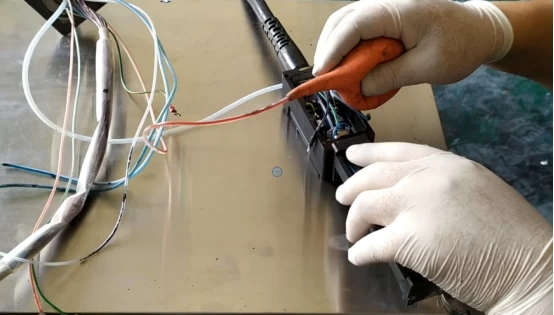

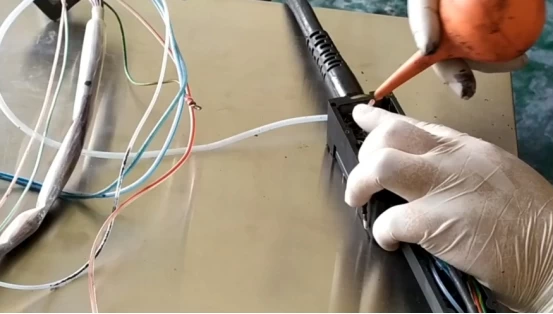

If it can't blow through, we'll use the ear ball to suck some detergent first, then insert it into the other end of the pipe to blow hard and inject some detergent into it:

After the injection of cleaning liquid, we can use a fine steel wire to gently poke it in at one end of the pipe. The front end of the wire must be smooth, not sharp, otherwise it is easy to break the pipe, and then poke it in, and then push it all the way back and forth:

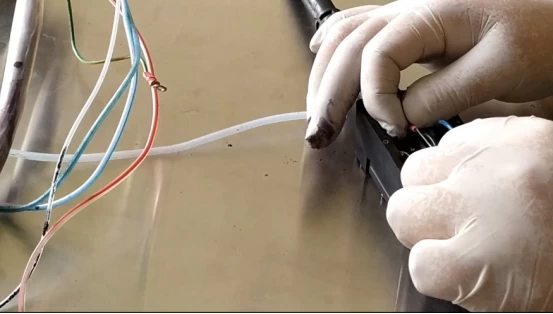

If the steel wire can't be pushed, then we'll inject some cleaning fluid into it:

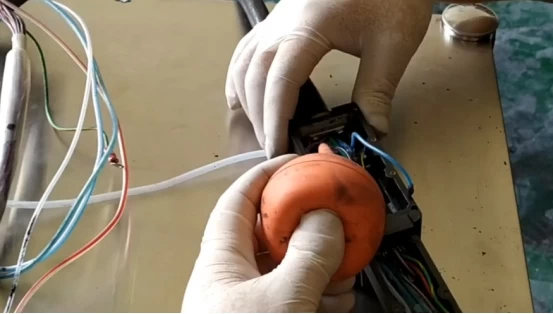

Then continue to dredge with steel wire:

Then, if one end can not be pushed, we will dredge it with steel wire from the other end. The treatment method is the same as just now:

If the steel wire can't be pushed forward, use the ear ball to suck up the cleaning solution, and then inject it into the pipe,

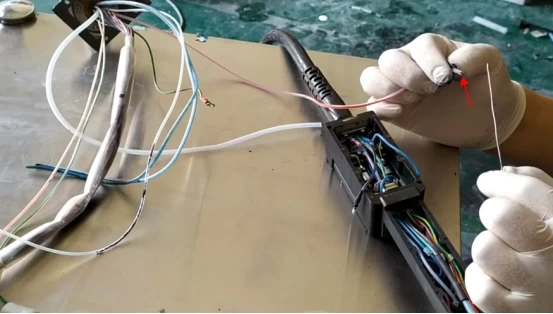

This shows that the pipe has been dredged:

The treatment method of the cleaning tube is the same as that of the ink supply tube:

After we dredge these two pipes, there is a recovery pipe. The treatment method of the recovery pipe is the same. We dredge the pipe from one end or the other end with steel wire. In the process of dredging, we use ear ball to suck some detergent, then blow some detergent from one end, and then dredge it with steel wire. Until the pipe is blown from one end with an ear ball and the cleaning solution can be sprayed from the other end: