How to handle the recycling failure of Citronix ci1000 inkjet printer?

The most common is nozzle blockage, which can be divided into two cases.

One is completely blocked, that is, when the machine starts up normally, there is no ink line coming down from the nozzle, the pressure and speed of the machine are normal, but there is no ink line coming down. This is completely blocked.

Another is that the ink line deviates and does not spray to the correct position of the recycling tank. That is, when printing normally, the ink line suddenly deviates. If the nozzle has not fallen, the nozzle is generally blocked:

Nozzle blockage, normal, we first wash the nozzle, that is, do not remove the nozzle, and then take the cleaning liquid to the nozzle spray a little cleaning liquid, sprayed after the cleaning liquid, and then normal boot to try.

If the nozzle is still blocked, then we need to remove the nozzle, because Citronix 3200/3300 does not have nozzle cleaning function, so we can only remove the nozzle, and then put the nozzle into the ultrasonic, ultrasonic wave put some cleaning fluid, and then use ultrasonic vibration cleaning, cleaning for hundreds of seconds, cleaning several times in a row, and then test whether the nozzle is clear.

Then if we remove the nozzle, be careful to remove the two screws on the side:

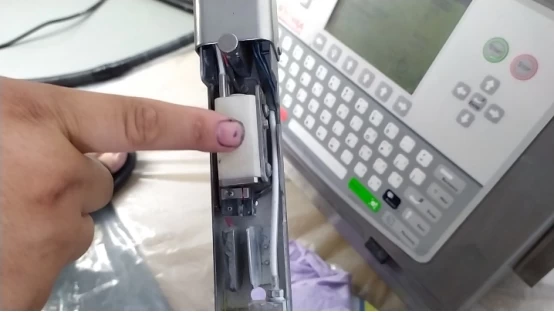

This white module is a spray gun:

Then the spray gun can take it out upward. After taking it out, the two screws of the nozzle can be removed. After removing, the nozzle can be removed. After the nozzle is removed, put the nozzle in the ultrasonic wave, put some cleaning fluid in the ultrasonic wave, and then vibrate, vibrate for five or six hundred seconds. After the vibration, stop for a few minutes, then vibrate again, stop for a few minutes, and then vibrate again. Vibrate several times continuously like this, then we install the nozzle, and then install the screw.

Because the screws here were removed:

So the ink line position will certainly change, we need to re-adjust, this needs us to know, we first loose this screw:

Then adjust the screw, which adjusts the front and rear of the ink line:

Then we loosen the screw:

Then adjust the screw below, adjust this one-word screw, can be used to adjust it around, spin it can adjust the ink line to the left and right, so that we will adjust it to the correct position of the recycling tank:

If this circle is a recycling tank, the ink line position should be at this location:

Ink lines can't be in the middle like this:

And then we look at it this way, it's left-leaning:

If we look at it this way, it's in the middle of the recycling bin:

Then we adjust it, then we can run, and then run for a while to see if it is stable, if stable, it means that we have adjusted, this is nozzle blockage, ink line bias, that is, our common recycling failure.