How to deal with charging and high-voltage faults of Citronix ci1000 inkjet printers?

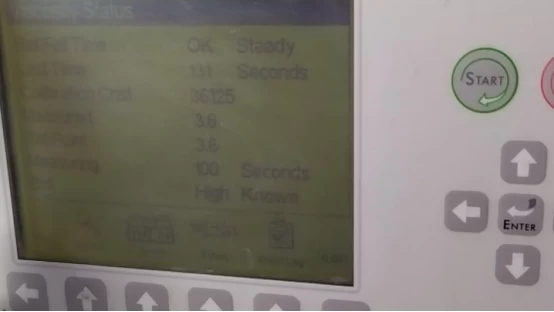

Then we look at the charging fault, we first need to look at the parameters, that is, whether the viscosity is right, whether OK is displayed:

Viscosity cannot be too low or too high, and if viscosity is not right, we should adjust the viscosity. If the ink viscosity is very thin, I do not need to tube it, let it automatically run, run for a day or so, may viscosity becomes higher, if you want viscosity to rise faster, directly to the ink tank to add new ink, if the viscosity is very high, then we let it automatically run, automatic operation, the solvent will automatically add to the ink tank, and then by mixing to reduce viscosity, which is the viscosity to see if normal.

If the viscosity is OK, but charging is still not possible, we look at the split, we look at it with a magnifying glass here:

See how the ink point splits through the charging slot, and if the point is a very round point of point by point, that means the point splits very well. If the point split is not good, that is to say, on a line, above a point a point, that is, the line is not separated, which shows that the point split is not good, we need to adjust the ink point.

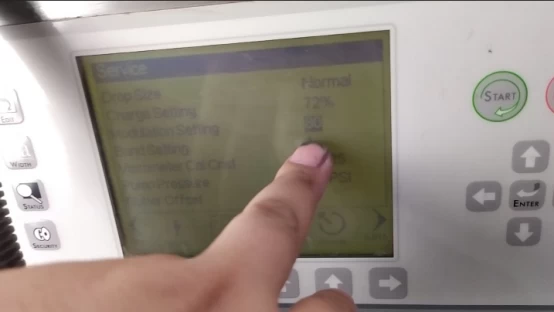

To adjust the ink point, we're going to adjust the modulation voltage:

We can turn it up a little bit, and then we'll use a magnifying glass to see the ink dot split until we see that the ink dot splits very well, and then we'll save the value, and then we'll let it run and see if the alert is still reported.

If the viscosity is ok, and then the ink point split is good, then we have to consider whether there is a problem with this charging pole, if the printing effect is not good, we should consider replacing this charging slot:

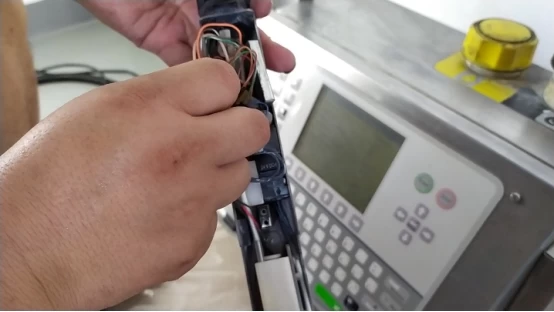

If the charging tank is to be replaced, we need to remove the two screws on the back:

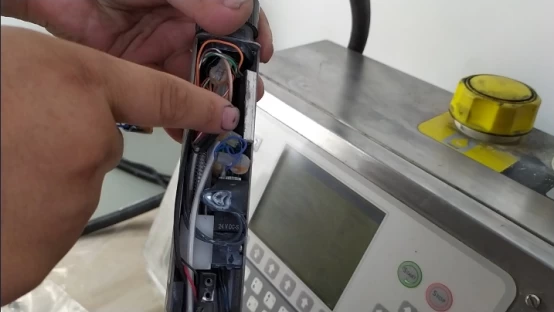

Then the whole can be pulled out:

This end is then connected to the phase amplifier:

It's a whole, and we can take this piece apart:

These lines should pay attention to, how originally connected, now or how to connect.

And then we take it down like this:

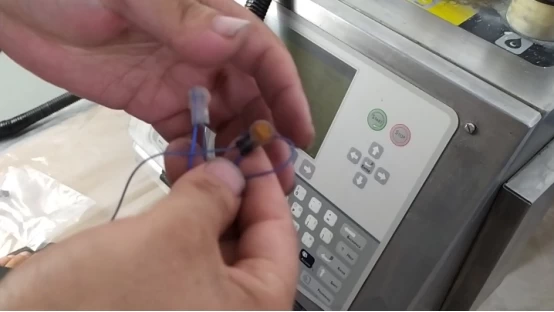

This end is connected to the phase amplifier:

Connect to the phase amplifier here:

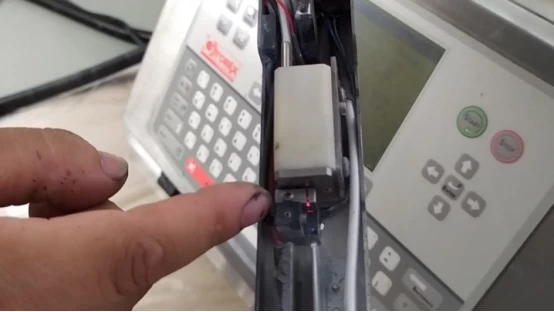

Let's replace the charging tank.

After we replace the new one, then the screws should not be tightened too tightly:

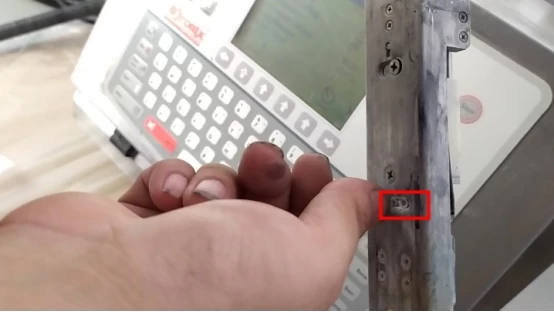

Then, let's look at the general position of the nozzle first, and we will match the position well:

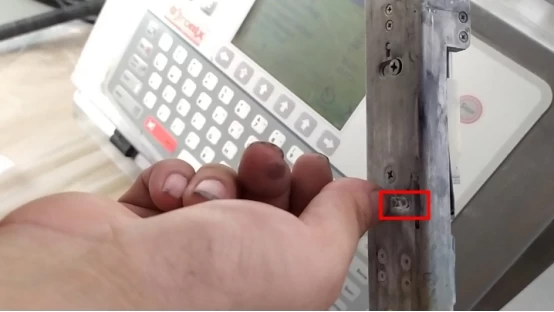

After the corresponding good position, and then change, the nozzle is certainly not moving, and then shoot off the ink line, we want to ensure that the ink line shot in the middle of the charging tank, because the ink line is through its middle through, if not in the middle, we want to adjust these two screws, let them slightly loose:

Then adjust the charging tank until the ink line passes through the middle of the charging tank:

There is also a high-pressure fault, when a high-pressure failure occurs, first open the nozzle cover, and then we see if the high-pressure deflector is dirty:

If it is very dirty, we use cleaning liquid to wash it dry clean, and then blow-dry it, must keep dry, must be very clean and dry, and then we turn on again, generally do this problem can be solved.