How to deal with the viscosity failure of the Domino white ink machine?

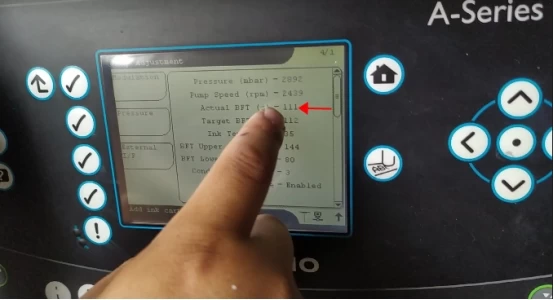

Viscosity failure means that the actual value above it does not show, only three asterisks, the value does not show:

In this case, there are several possibilities, the first possibility being that the viscometer is blocked:

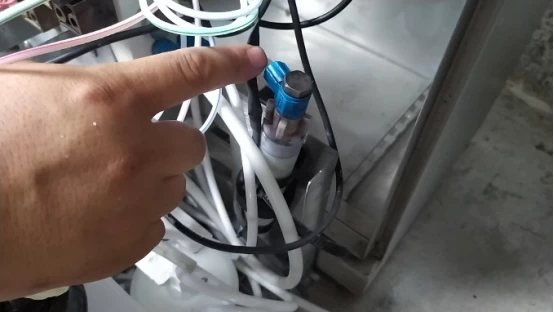

In the case of this viscometer blocking, first turn off the machine and remove the tubes above and below the viscometer:

After removal, we spray the cleaning fluid with the cleaning pot against the connector slot below:

Then see if the cleaning fluid can come out from above:

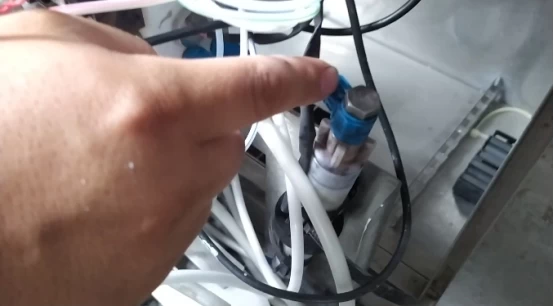

If the cleaning fluid does not come out, the viscosity meter is blocked. When the blow below, we can hear the sound of the crackling of steel beads inside, that is to say, there is no resistance, that means we clean it up.

Either we've been holding the cleaning pot, spraying the lower end, spraying it in, and then letting it go out until the cleaning fluid is very white, and then blowing the steel beads inside, there's a crackling sound, and then we'll connect the pipe.

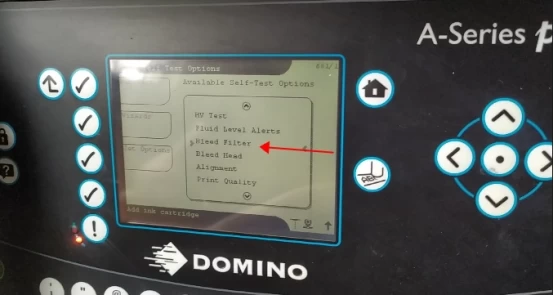

Once connected, we will select Bleed Filter in the Diagnostics:

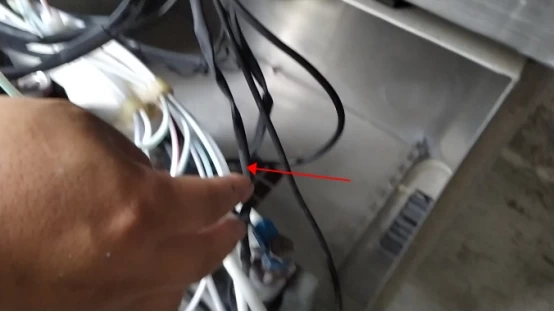

After the viscometer is connected, if the viscometer is not blocked, the viscosity is still not displayed, we will be the viscometer and ink interface board between the connection of this line to pull out, note must be in the shutdown state, and then reinstall it:

Then we turn on again to see if the viscosity will be displayed, if the viscosity does not show out, then we can change an ink interface board to try, if still not, then we need to replace a viscometer.

Another is that we look at where the pipeline has air leakage, if the ink supply line leakage, viscosity is not shown.

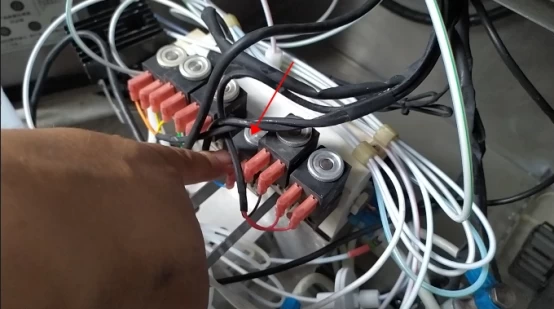

Look at the viscosity valve when we detect whether it will make a crackling sound, whether it will beat, if we do not hear the sound, indicating that it is not detected at all, then we can also remove this viscosity solenoid valve, remove it and then clean it, and then we install it: