Videojet latest machines: simplicity series

With the withdrawal of the Videojet 1000 series of machines from the market, the models that replaced it are: 1240, 1280, 1580, 1880. These models are collectively referred to as the Simplicity series.

These models are used in different products and different scenarios. Let's talk about these models from several aspects.

1. Differences between simplicity series and old 1000 series:

1) Human-computer interaction: Simplicity series still uses the 1000 series of sprinklers and liquid systems, the biggest improvement is the use of human-computer interaction interface, eight-inch computer touch screen, simple and easy to operate. Suitable for manufacturers with high employee turnover rates, it has built-in features such as the SIMPLICiTY™ user interface, designed to reduce operator intervention in the printer and eliminate potential operational errors with a directly viewed flat panel touchscreen.

2) Ink core system reform: Simplicity adopts the replacement service module instead of replacing the entire ink core, which greatly reduces the procurement cost and reduces environmental pollution.

3)Convenience and ease of operation: The replacement of the ink core of the Videojet 1000 series machine requires professional technicians, while the latest Simmlicity series does not require professional technicians, as long as 5 minutes to replace the service module. Built-in, easy-to-understand "how-to" videos are also available to guide you through basic tasks that don't require extensive training

4)Eco-friendly: The Videojet Smart Cartridge™ system is dirt-free, waste-free, error-free, drains all ink/solvent from cartridges/cartridges, and provides extra leak protection during transport and handling. The Videojet SmartCell™ design also simplifies routine maintenance. The picture of each service module is as follows:

Service module of the 1580 machine: red

Service module of the 1880 machine: green

5) Production flexibility: Maintain production flexibility without sacrificing quality, when intermittent printing is required, whether for short-term production, seasonal production, or SKU surge, Videojet 1240 offers a range of features to ensure you are supported.

6) Reduced production costs: For manufacturers who are budget-sensitive and plan to buy a "printer that runs to failure", Videojet simplicity offers a suitable total cost of ownership solution. User-performed maintenance allows you to self-plan and install downtime to meet your production needs. Our Videojet SmartCell™ service modules only need to be replaced once a year, and operators can complete the replacement in less than 5 minutes

2. Machine application range:

The machines of the Videojet 1240 and 1280 are widely used and can be applied to beverages, food, construction, chemicals, medical treatment, etc.

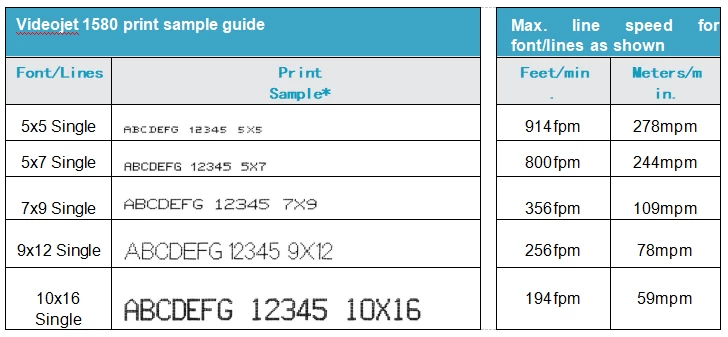

Videojet 1580 machines are used in applications where production lines require further speed and where complex coding is required.

Videojet 1880 machines are mainly used for customers with special needs, such as Industry 4.0 automation, and the protection class requires IP66.。

3. Print content

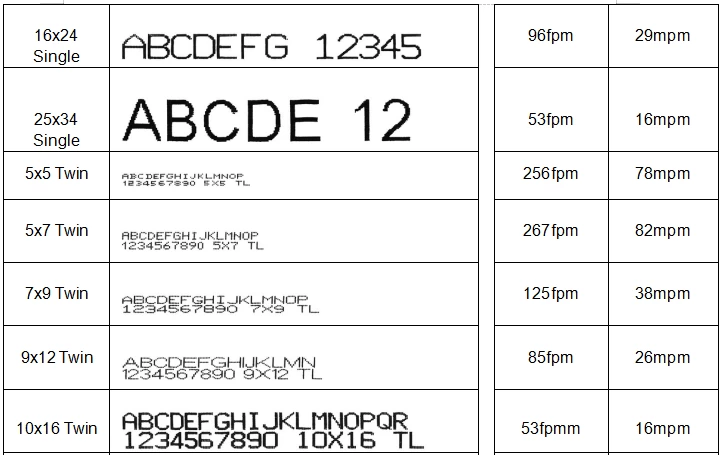

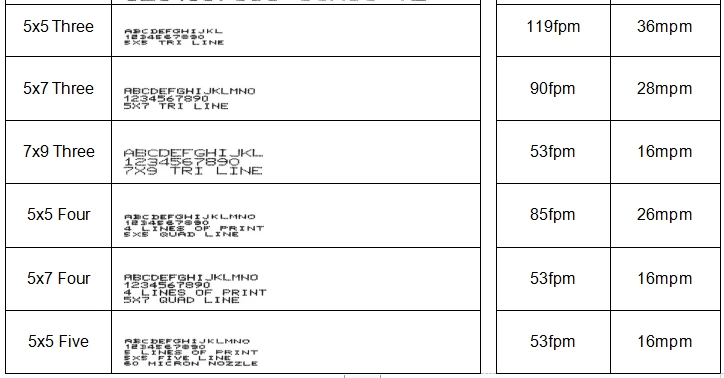

1)Effects of various dot matrix printing:

The contents that can be printed by the 1240 and 1280 machines are as follows:

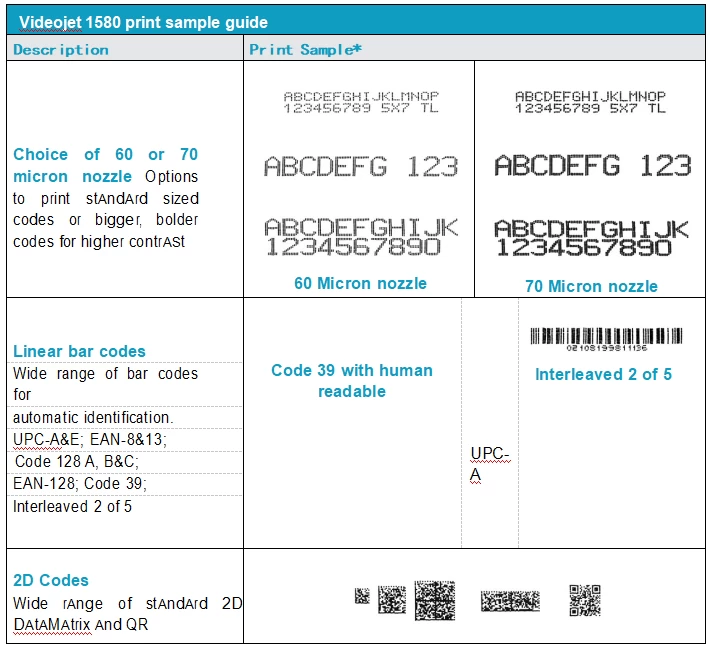

Linear bar code (various bar codes for automatic identification. UPC-A & E; ean-8 & 13; Code 128 A, B & C; EAN-128; Code 39; I25 code),

QR codes (various standard 2D DataMatrix and QR codes),

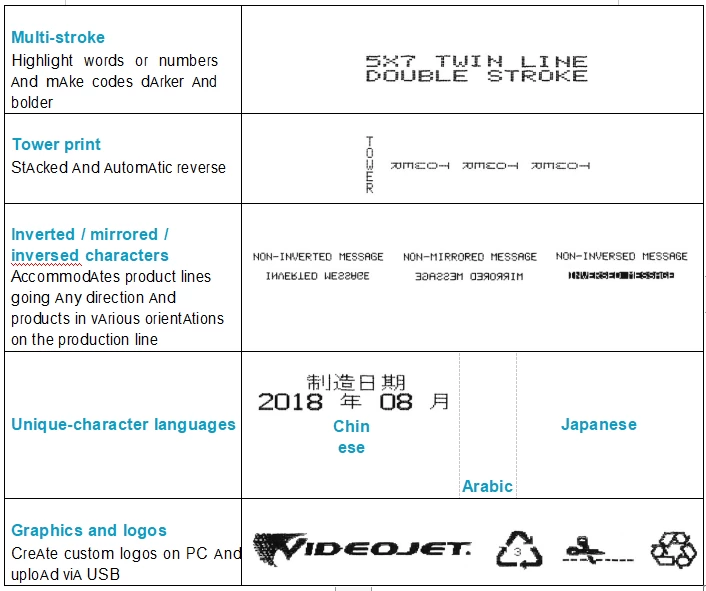

Multi-stroke (highlighting words or numbers and blacking and bold encoding), Tower Printing (stacking and auto-inversion),

Inverted/Mirrored/Inverted characters (for product lines with any orientation and products in various directions on the product line),

Unique languages,

Graphics and logos (create custom logos on a PC and upload via USB)

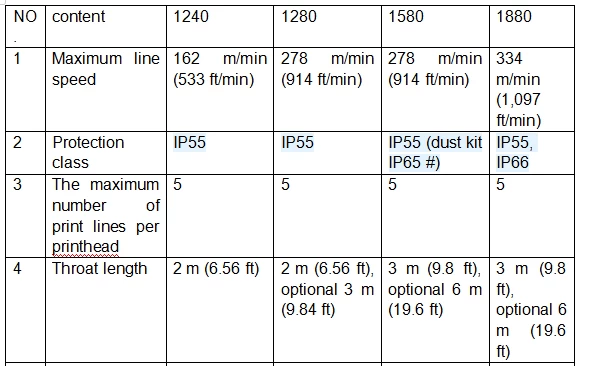

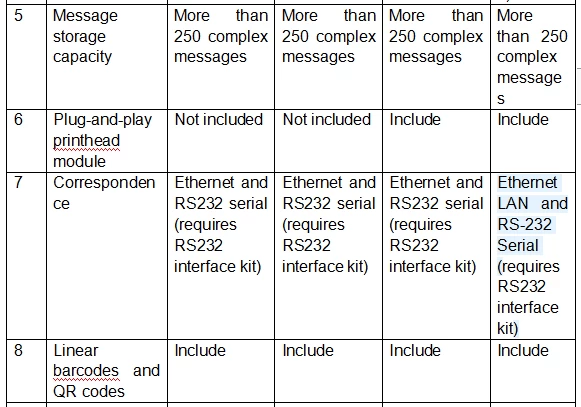

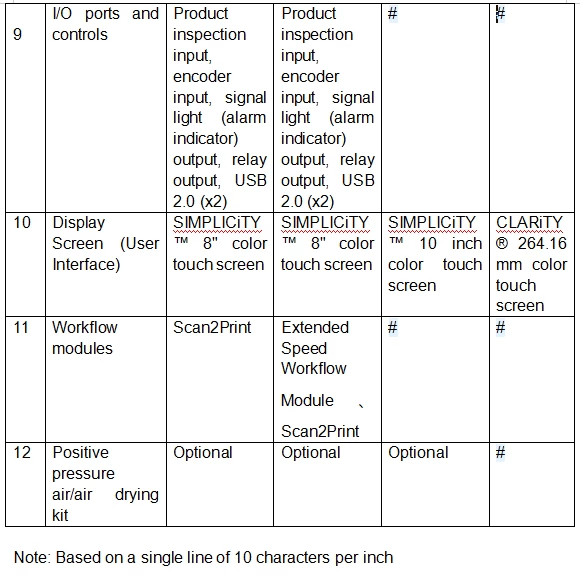

Here's the difference between 1240, 1280, 1580, 1880: