Videojet 8520 Machines:Installation Considerations

Don’t use brute force when installing the cartridge, install it gently.

When unplugging, also pull gently because there is a chip. If you use brute force, the ink cartridge or the machine will be damaged.

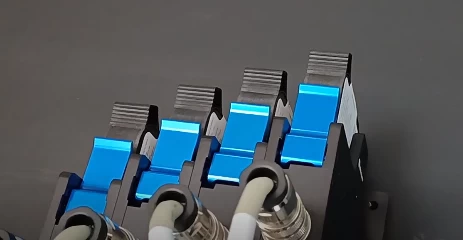

When installing the data cable, it must be clamped tightly and not shaken.

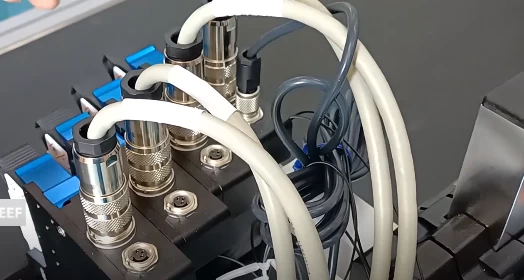

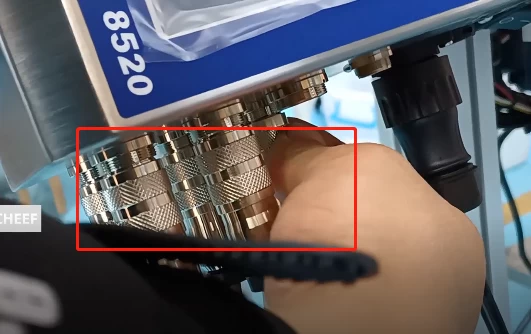

The plug on the controller should also be tightened, and there should be no shaking.

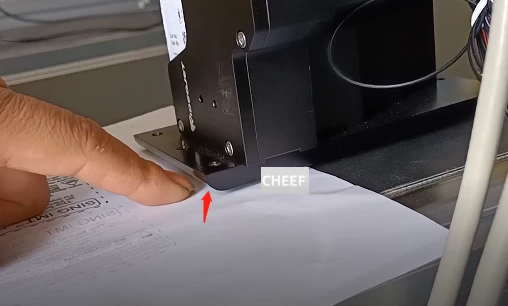

The nozzle must be perpendicular to the conveyor belt, otherwise there will be splicing problems.

Note that the direction is from left to right, be sure to pay attention to which direction the conveyor belt turns.

If printing a product, the distance between the nozzle and the product should be within 2mm, that is, the gap between the nozzle and the product should be within 2mm, not greater than 2mm.

The connecting wire of the encoder must be tightened and connected in place.

The encoder must have resistance and cannot slip.

When the fixing rod is installed, it must be tightened and there should be no shaking.

If you do not use the machine for more than half an hour, be sure to pull out the ink cartridge and cover the cover, so that it will not dry out, otherwise it will affect the printing effect. Put the closed ink cartridge aside and install it when you need it.

Special attention: whether it is installing ink cartridges or pulling out ink cartridges, the machine is in a power-off state!