How to handle the recovery failure of the Domino white ink machine?

First, let's look at the ink line at normal power-on, because there are several possibilities for recycling failures.

First, let's see if the ink line hits the recycling tank:

If you hit the recycling tank and the recycling tank is also recycled, but it reports a recycling failure, let's look at our ink viscosity.

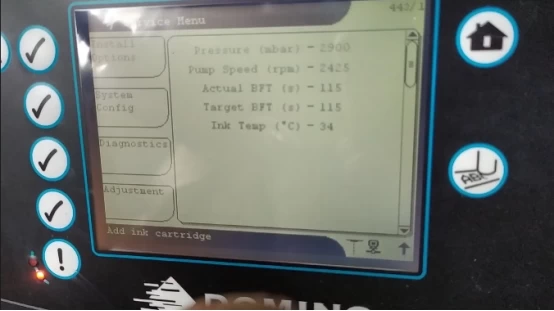

First of all, let's look at whether the ink viscosity is exactly right, if the viscosity is very low, there will be this recovery failure, because it is less conductive:

Then let's look at this viscosity if normal, it is also recycled, and then also reported recycling failure, then we this recycling component may be broken, to replace it, after it should be good:

Another is that the ink wire did not hit the recycling tank, there are two possibilities, one is nozzle blocking, and the other is the nozzle screw loose, shaking, and then lead to a change in the position of the ink line.

Let's see if it's blocked, we'll see if the ink line is very straight, the position of the ink line is high or low, is left or right, this we can use the eye to observe:

Generally are caused by nozzle blocking, as long as your nozzle did not fall, no violent shaking, generally speaking, the nozzle blockage and then cause the ink line bias.

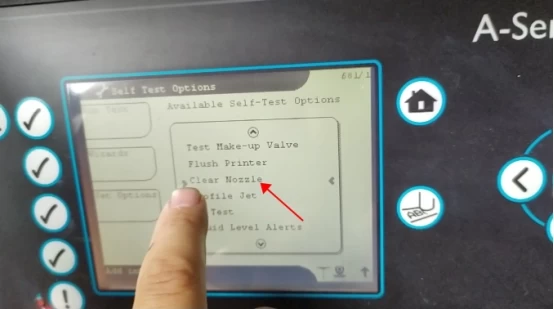

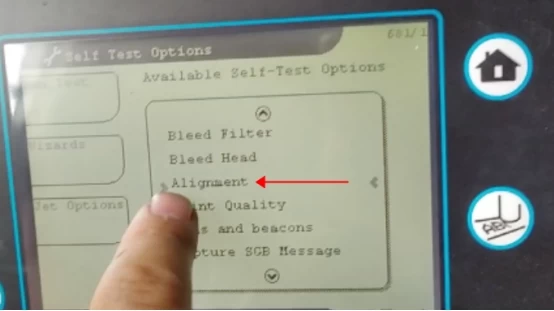

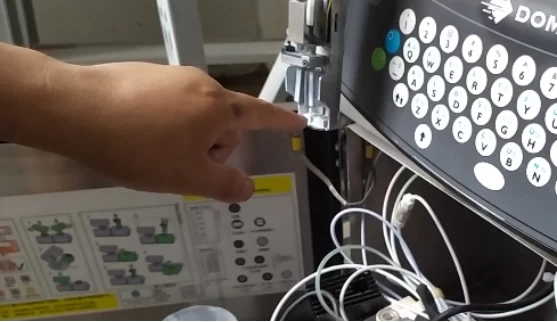

If it is determined that the nozzle is blocked, we need to do nozzle cleaning, we find the "software", find the "diagnosis" and there is a nozzle cleaning option inside:

I select it and click Next, which will clean the nozzle:

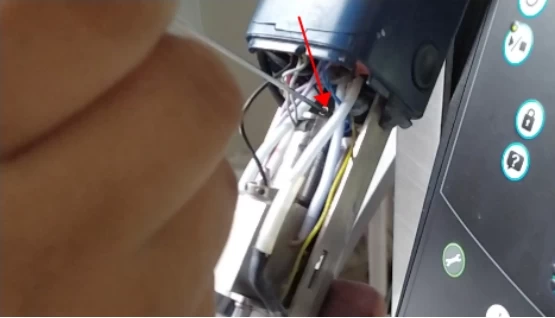

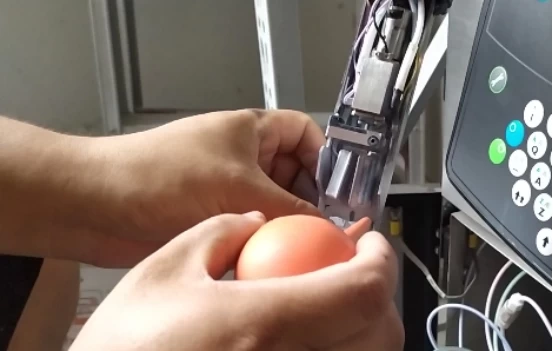

In the process of cleaning the nozzle, we will use the cleaning pot against our nozzle, and then spray the cleaning liquid:

Because when the nozzle is cleaned, it produces a negative pressure, it will be recycled from the nozzle this dirty thing, and then this time we have to clean the nozzle, it will suck the solvent cleaning liquid together, and then by the way the dirty things are removed, once it does not work we wash it a few times more, until the nozzle washed.

This nozzle cleaning is such cleaning, wash a few more times, with the software above this nozzle cleaning, and then we hold the cleaning pot, just like I just did, against the hole in the middle of this nozzle, spray point cleaning liquid. Wash several times more until the ink line of the nozzle is in the correct position.

Another is to say, the nozzle is not blocked, the ink line is biased caused, so we need to adjust the ink line to the original suitable position.

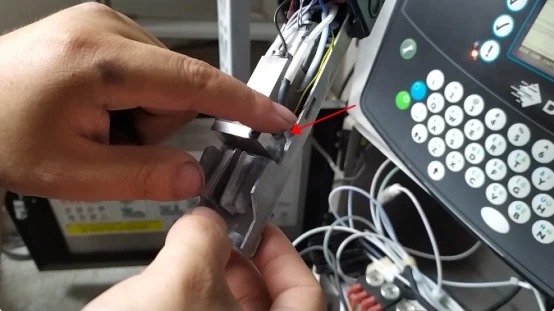

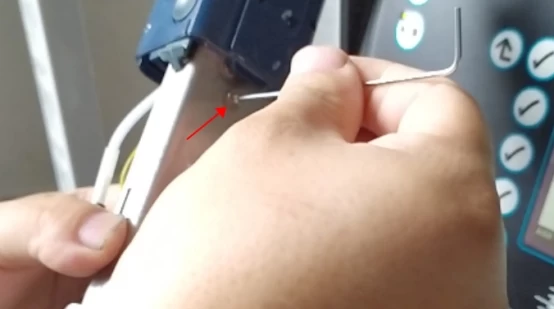

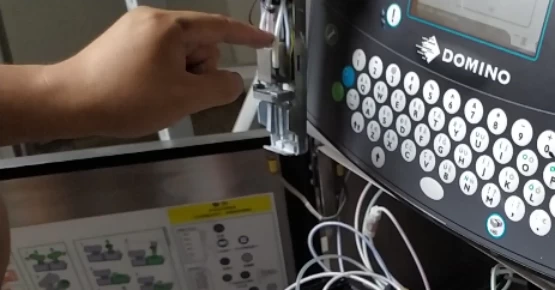

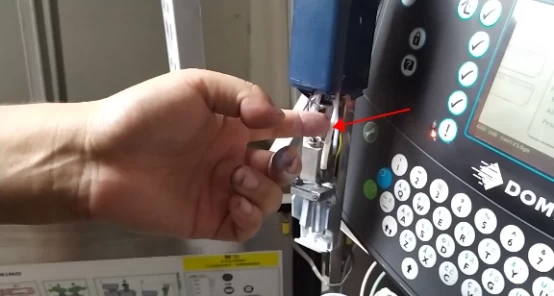

If we adjust the ink wire, here is a fixed screw, whether it is forward or left to right, this screw must be loosened, screw it back, the screw loosened a circle and a half or so:

Once loosened, then it has a black screw on it, and if we adjust it, we can adjust the left and right of the ink line:

If we adjust the screw behind it, we can adjust the front and back of the ink wire:

After adjusting, we tighten this fixing screw to it:

If the ink line comes out, we want to adjust the ink line, we have to use the "alignment":

After hitting the ink line with alignment, then we adjust the ink line around and forth according to what we just said, until the ink line returns to the correct position of the recycling tank, which is a recycling failure.

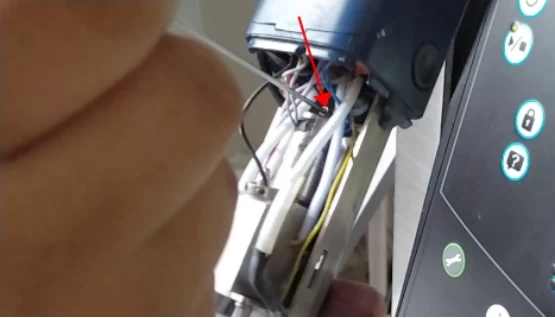

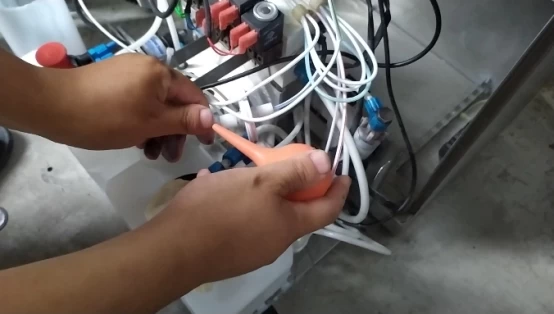

Another fault is the blockage of the recycling line, that is to say, the ink line hit the recycling tank, the recycling tank is not recycled. We need to remove this recycling filter:

After removal, then one end of the tube is passed into the ink shunt block, and the other end is passed to the nozzle's recycling tube:

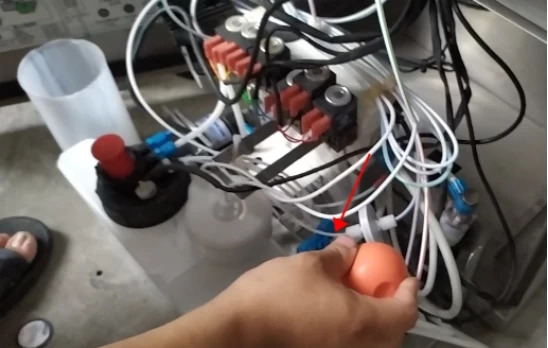

After we take it off, we take an earwash ball, and then we plug it in and blow it hard:

Let's see if there's ink coming out of this front end, and if there's no ink coming out, the tube is stuck:

If the tube is blocked, we can unplug it from here:

And then we still blow from here:

Here, if the ink is out, it means that the tube is not blocked:

That must be blocked in the following section, and this recycling component below is blocked. We can unplug the recycled component, which means that if we lift it up, it will fall from here:

Then we'll install this tube on it:

Then we blow the tube with an ear-washing ball to see if we can blow it:

If it can be blown, the recycling line is not blocked, and then the recycling component is not blocked:

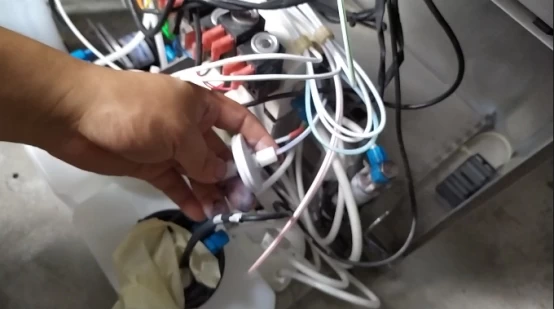

That means the recycling tank is blocked:

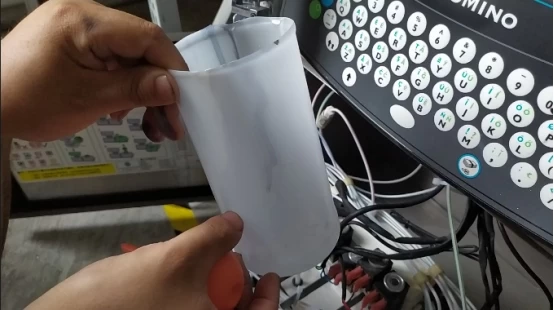

If the recycling tank is blocked, we take a container and pour it into solvents or cleaning fluids at such a high level to soak it:

Then we plug the print head in, then let the solvent soak the recycling tank, then soak it for a while, and then we try again.

If the tube is blocked:

We use a wire from one end of the pipe or the other, and then poke it in, gently, not with brute force, because if you use brute force, the pipe is easy to be punctured by it.

This is not recycled, the ink line hits the recycling tank, but does not recycle, and then is also reported recycling failure.