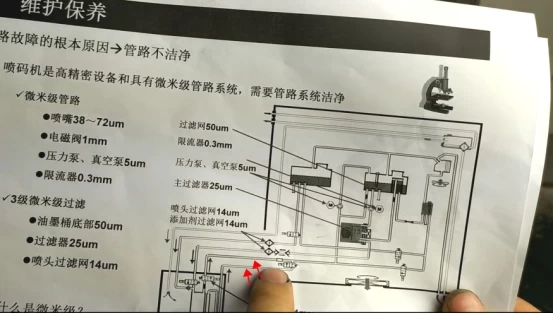

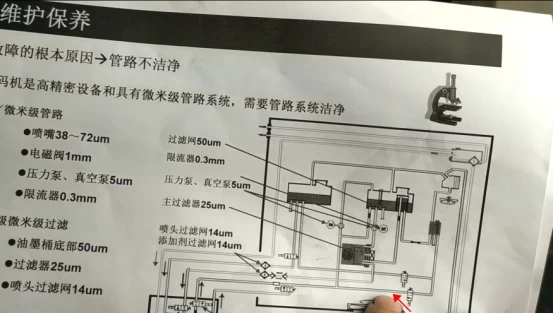

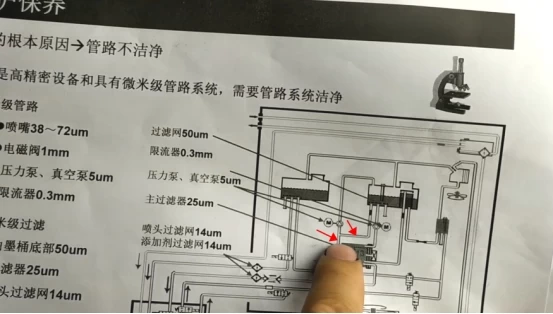

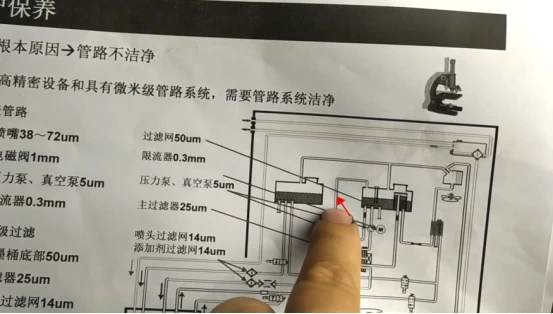

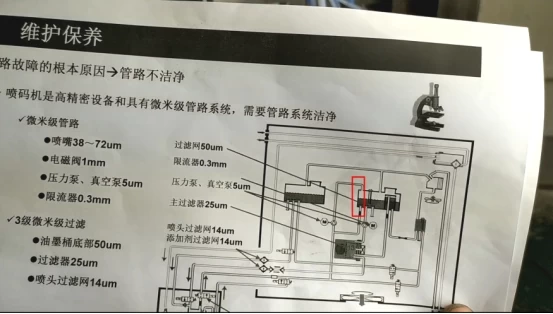

Detailed explanation of ink path of Imaje 9040 inkjet printer

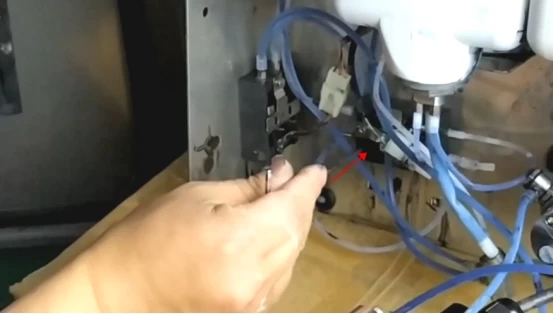

Part of the ink wire enters the recycling tank and is then recycled through the recycling tube:

And then most of it goes through this blue ink return tube:

Then go back to this position:

This position includes the return of the recovery tube, which is then eventually passed by the vacuum pump.

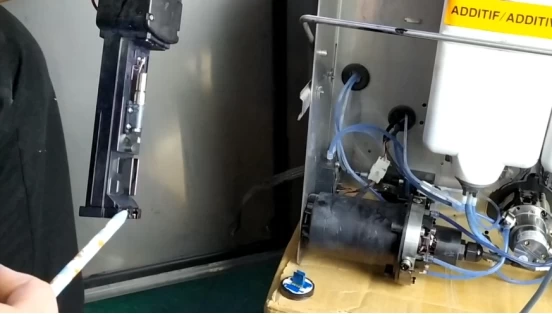

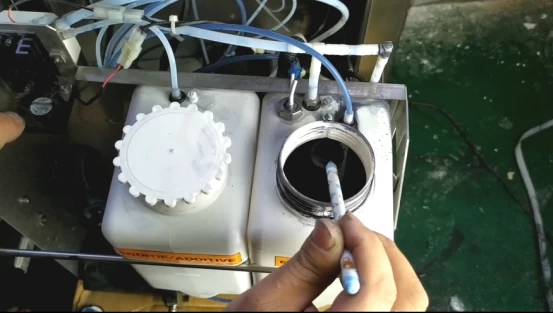

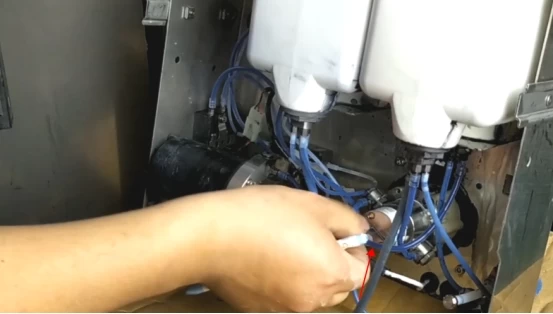

This is a scale bucket, mainly used to measure viscosity:

This is the viscometer:

There is a calibration tube in the middle of the viscosity meter, and then into the main ink tank, it flows down, ink flow through the main ink tank to the viscometer, from the low level to the high level, and then through this time to calculate the viscosity, and then to the high level, the viscosity valve will immediately open, will be pumped through the vacuum pump of the viscometer ink to pump away.

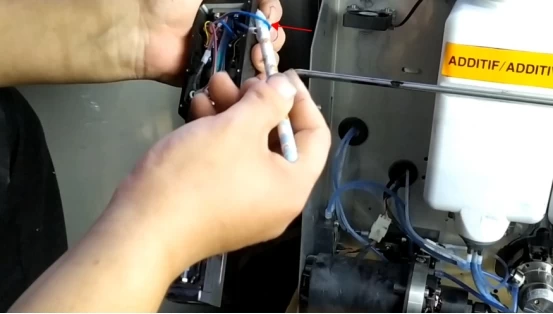

The viscosity is calculated by flowing this time, and if a solvent needs to be added, this is the solvent valve:

The solvent valve opens and injects the solvent into the ink path.

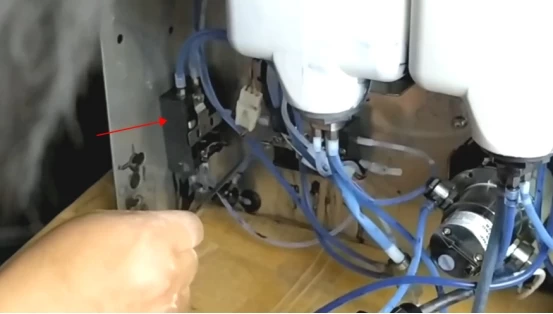

This is the viscosity valve:

The above one is the cleaning valve:

Here's the recycling valve:

If the viscosity valve measures a high viscosity value, the solvent addition valve will open, it will be directly into the ink into the solvent, and then dilute the ink.

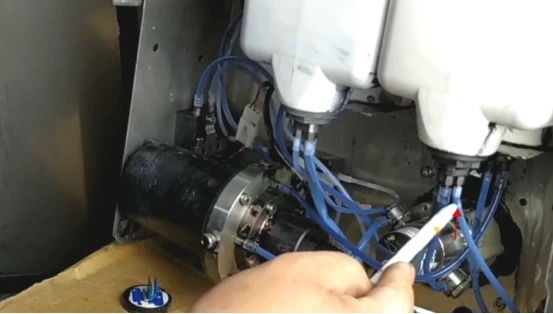

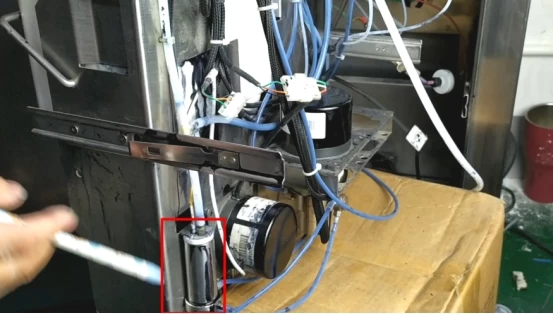

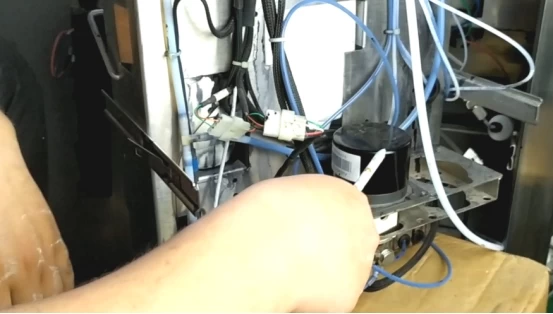

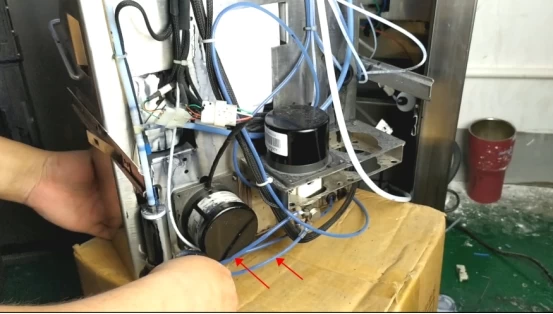

The main one is a vacuum pump:

But it has three tubes, all three of which are a recycling path, one is a blue tube above the nozzle, and one is the one behind the direct nozzle, both of which mean all return to the main ink tank:

Then the other way is also directly back to the main ink tank, and then through the other end of the vacuum pump, directly back to our main filter.

This is the vacuum pump:

It follows two back-inks from the nozzle:

And this ink for the viscometer:

All three tubes are to the vacuum pump.

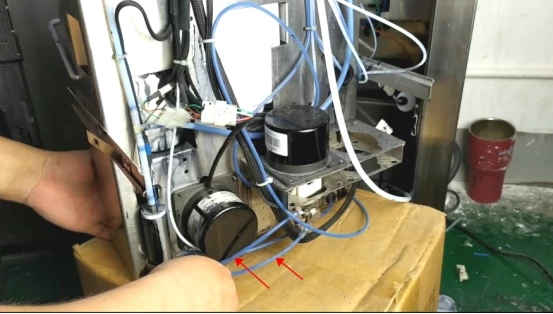

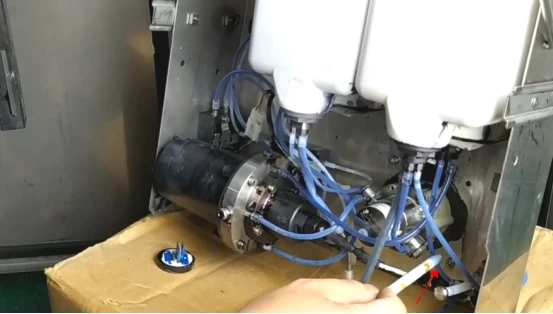

There is also a vacuum pump, which flows into two tubes:

On the other side is a tube:

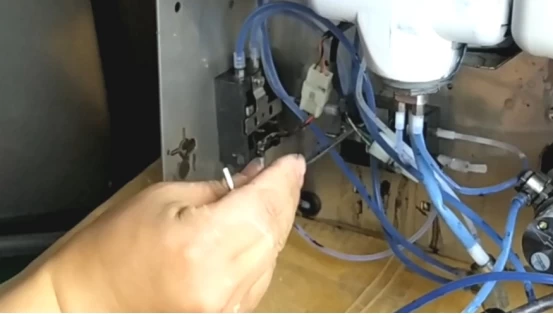

It's these downward and upward tubes that end up in the main ink tank:

These two tubes enter the main ink tank directly from below:

This is the basic ink road explanation.

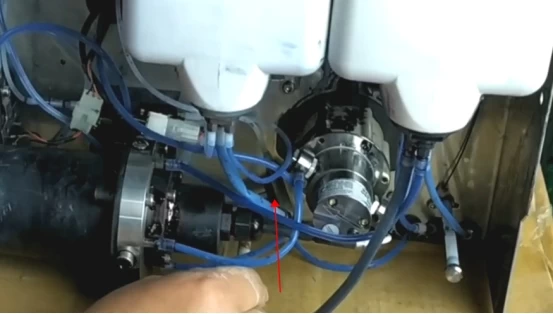

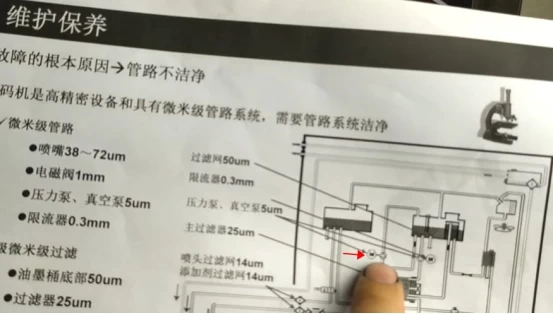

Look at a few places where finite currents, one is the main filter side back to the main ink tank side, this tube finite flower:

The viscometer has a calibration tube that acts the same as a current limiter:

It is a certain viscosity of the tube through this small hole, and then flow full of viscosity meter time, through this to calculate viscosity.

There is also a vacuum pump recycling we just said, recycling here also has a current limiter: